Page 839 - 2006 HARLEY FLSTCI SERVICE MANUAL

P. 839

3.19 5

3

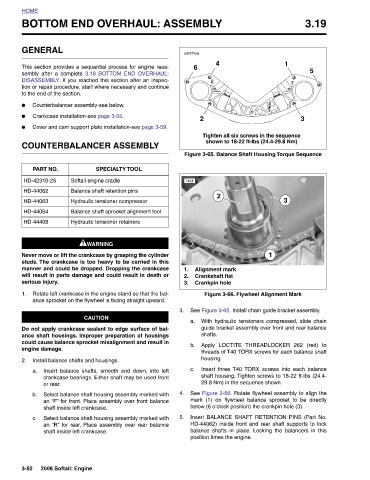

Tighten all six screws in the sequence shown to 18-22 ft-lbs (24.4-29.8 Nm) Figure 3-65. Balance Shaft Housing Torque Sequence Figure 3-66. Flywheel Alignment Mark See Figure 3-65. Install chain guide bracket assembly. With hydraulic tensioners compressed, slide chain guide bracket assembly over front and rear balance threads of T40 TORX screws for each balance shaft Insert three T40 TORX screws into each balance shaft housing. Tighten screws to 18-22 ft-lbs (24.4- 29.8 Nm) in the sequence shown. See Figure 3-66. Rotate flywheel assembly to align the mark (1) on flywheel balance sprocket to be directly below (

1 3 1 THREADLOCKER 262 (red) to

Y 4 2 Alignment mark Crankshaft flat Crankpin hole Apply LOCTITE housing. position times the engine.

BOTTOM END OVERHAUL: ASSEMBL

2 shafts.

s0227x3x 6 7451 a. b. c.

2.

1.

3.

3. 4. 5.

Balance shaft sprocket alignment tool

SPECIALTY TOOL

GENERAL This section provides a sequential process for engine reas- sembly after a complete 3.18 BOTTOM END OVERHAUL: DISASSEMBLY. If you reached this section after an inspec- tion or repair procedure, start where necessary and continue to the end of the section. Counterbalancer assembly-see below. Crankcase installation-see page 3-55. Cover and cam support plate installation-see page 3-59. COUNTERBALANCER ASSEMBLY PART NO. Softail engine cradle HD-42310-25 Balance shaft retention pins HD-44062 Hydraulic tensioner compressor HD-44063 HD-44064 Hydraulic tensioner retainers HD-44408 1WARNING 1WARNING Never move or lift the crankcase by g

HOME ● ● ● 1. 2. a. b. c. 3-52