Page 11 - Peak Period Planning Document-ENGLISH - 2020_Neat

P. 11

PEAK PERIOD - QUICKFIND BEST PRACTICES PRODUCT

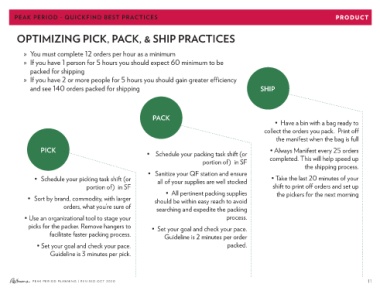

OPTIMIZING PICK, PACK, & SHIP PRACTICES

» You must complete 12 orders per hour as a minimum

» If you have 1 person for 5 hours you should expect 60 minimum to be

packed for shipping

» If you have 2 or more people for 5 hours you should gain greater efficiency

and see 140 orders packed for shipping SHIP

PACK

• Have a bin with a bag ready to

collect the orders you pack. Print off

the manifest when the bag is full

PICK • Schedule your packing task shift (or • Always Manifest every 25 orders

portion of) in SF completed. This will help speed up

the shipping process.

• Sanitize your QF station and ensure

• Schedule your picking task shift (or all of your supplies are well stocked • Take the last 20 minutes of your

portion of) in SF shift to print off orders and set up

• All pertinent packing supplies

• Sort by brand, commodity, with larger should be within easy reach to avoid the pickers for the next morning

orders, what you’re sure of searching and expedite the packing

• Use an organizational tool to stage your process.

picks for the packer. Remove hangers to • Set your goal and check your pace.

facilitate faster packing process. Guideline is 2 minutes per order

• Set your goal and check your pace. packed.

Guideline is 3 minutes per pick.

PEAK PERIOD PLANNING | REVISED OCT 20 20 11