Page 209 - FreesStyler® Installation and Startup

P. 209

®

INSTALLATION AND STARTUP

Chapter 10 Initial Startup

Startup Procedure

SCC

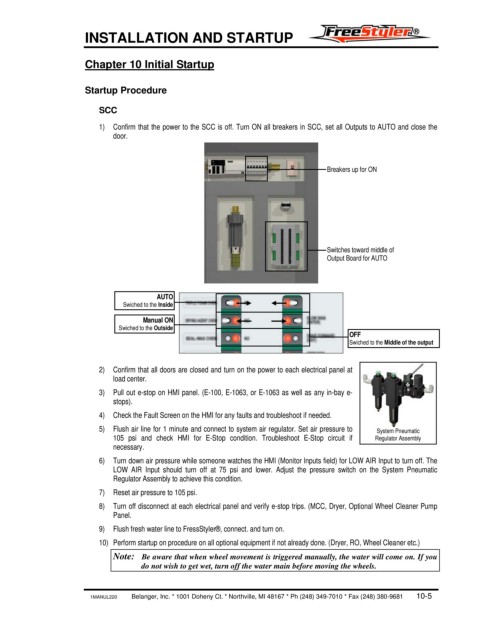

1) Confirm that the power to the SCC is off. Turn ON all breakers in SCC, set all Outputs to AUTO and close the

door.

Breakers up for ON

Switches toward middle of

Output Board for AUTO

AUTO

Swiched to the Inside

Manual ON

Swiched to the Outside

OFF

Swiched to the Middle of the output

2) Confirm that all doors are closed and turn on the power to each electrical panel at

load center.

3) Pull out e-stop on HMI panel. (E-100, E-1063, or E-1063 as well as any in-bay e-

stops).

4) Check the Fault Screen on the HMI for any faults and troubleshoot if needed.

5) Flush air line for 1 minute and connect to system air regulator. Set air pressure to System Pneumatic

105 psi and check HMI for E-Stop condition. Troubleshoot E-Stop circuit if Regulator Assembly

necessary.

6) Turn down air pressure while someone watches the HMI (Monitor Inputs field) for LOW AIR Input to turn off. The

LOW AIR Input should turn off at 75 psi and lower. Adjust the pressure switch on the System Pneumatic

Regulator Assembly to achieve this condition.

7) Reset air pressure to 105 psi.

8) Turn off disconnect at each electrical panel and verify e-stop trips. (MCC, Dryer, Optional Wheel Cleaner Pump

Panel.

9) Flush fresh water line to FressStyler®, connect. and turn on.

10) Perform startup on procedure on all optional equipment if not already done. (Dryer, RO, Wheel Cleaner etc.)

Note: Be aware that when wheel movement is triggered manually, the water will come on. If you

do not wish to get wet, turn off the water main before moving the wheels.

1MANUL220 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 10-5