Page 74 - DryLite® Dryers

P. 74

®

DRYLITE DRYER

Chapter 6: Installation of DryLite® - Side Flip Air Cannons™

Frame Assembly

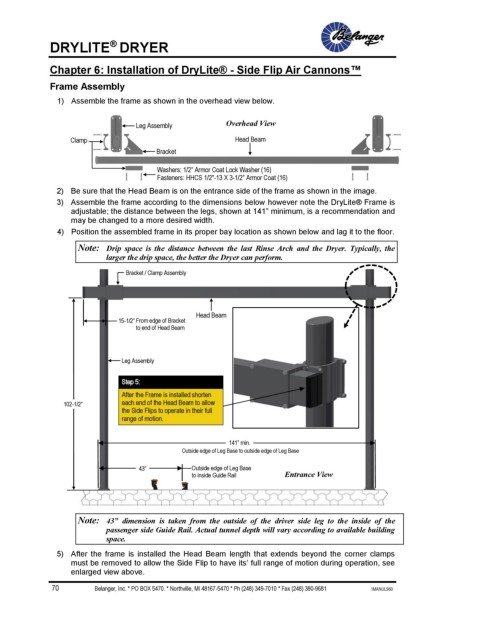

1) Assemble the frame as shown in the overhead view below.

Leg Assembly Overhead View

Clamp Head Beam

Bracket

Washers: 1/2” Armor Coat Lock Washer (16)

Fasteners: HHCS 1/2"-13 X 3-1/2” Armor Coat (16)

2) Be sure that the Head Beam is on the entrance side of the frame as shown in the image.

3) Assemble the frame according to the dimensions below however note the DryLite® Frame is

adjustable; the distance between the legs, shown at 141” minimum, is a recommendation and

may be changed to a more desired width.

4) Position the assembled frame in its proper bay location as shown below and lag it to the floor.

Note: Drip space is the distance between the last Rinse Arch and the Dryer. Typically, the

larger the drip space, the better the Dryer can perform.

Bracket / Clamp Assembly

Head Beam

15-1/2” From edge of Bracket

to end of Head Beam

Leg Assembly

Step 5:

After the Frame is installed shorten

102-1/2” each end of the Head Beam to allow

the Side Flips to operate in their full

range of motion.

141” min.

Outside edge of Leg Base to outside edge of Leg Base

43” Outside edge of Leg Base

to inside Guide Rail Entrance View

Note: 43” dimension is taken from the outside of the driver side leg to the inside of the

passenger side Guide Rail. Actual tunnel depth will vary according to available building

space.

5) After the frame is installed the Head Beam length that extends beyond the corner clamps

must be removed to allow the Side Flip to have its’ full range of motion during operation, see

enlarged view above.

70 Belanger, Inc. * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL960