Page 14 - Titan VPS™

P. 14

TITAN VPS™

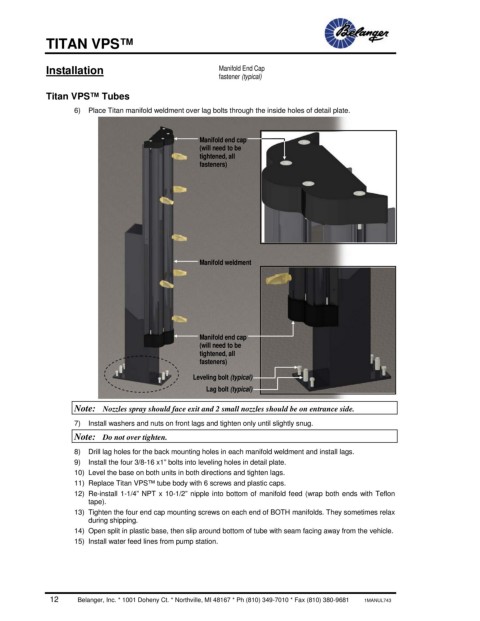

Installation Manifold End Cap

fastener (typical)

Titan VPS™ Tubes

6) Place Titan manifold weldment over lag bolts through the inside holes of detail plate.

Manifold end cap

(will need to be

tightened, all

fasteners)

Manifold weldment

Manifold end cap

(will need to be

tightened, all

fasteners)

Leveling bolt (typical)

Lag bolt (typical)

Note: Nozzles spray should face exit and 2 small nozzles should be on entrance side.

7) Install washers and nuts on front lags and tighten only until slightly snug.

Note: Do not over tighten.

8) Drill lag holes for the back mounting holes in each manifold weldment and install lags.

9) Install the four 3/8-16 x1” bolts into leveling holes in detail plate.

10) Level the base on both units in both directions and tighten lags.

11) Replace Titan VPS™ tube body with 6 screws and plastic caps.

12) Re-install 1-1/4” NPT x 10-1/2” nipple into bottom of manifold feed (wrap both ends with Teflon

tape).

13) Tighten the four end cap mounting screws on each end of BOTH manifolds. They sometimes relax

during shipping.

14) Open split in plastic base, then slip around bottom of tube with seam facing away from the vehicle.

15) Install water feed lines from pump station.

12 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (810) 349-7010 * Fax (810) 380-9681 1MANUL743