Page 1239 - Foton Workshop Manual - Auman EST-M

P. 1239

Body - Body assembly BW - 1

Body assembly IN

Sheet metal

1. Sheet metal operation process DI

a. Damage confirmation. Clean the damaged part and confirm the degree of damage, to define the repair

method. EG

b. Remove the sheet metal part. Remove the damaged sheet metal part from the original body with cutting or

other methods.

TR

c. Level the sheet metal part. Based on the damage degree of sheet metal part, level the sheet metal part with

the appropriate sheet metal tools and fine-tune the surface flatness of sheet metal part.

AX

d. Carry out the annealing treatment. Carry out the annealing treatment, to restore the original shape and

thickness of the sheet metal part and relief the tensile or extrusion stress, so as to maintain the rigidity and

FR

strength of sheet metal part.

e. Apply the epoxy paint. The epoxy paint inside of the sheet metal part may fall off or be damaged due to the

hammering process, so it should be applied with a layer of epoxy paint. ST

The above sheet metal operation process applies to the sheet metal parts with a small degree of damage;

if the body is collided seriously, and the frame is damaged, the frame and the body should be correcred, BR

the operation would be more difficult.

BW

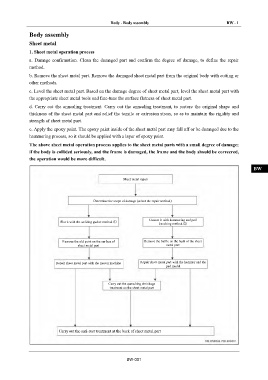

Sheet metal repair

EL

Determine the scope of damage (select the repair method)

Correct it with hammering and pad

Flat it with the welding gasket method ①

knocking method ②

Remove the old paint on the surface of Remove the baffle on the back of the sheet

sheet metal part metal part

Repair sheet metal part with the meson machine Repair sheet metal part with the hammer and the

pad model

Carry out the quenching shrinkage

treatment on the sheet metal part

Carry out the anti-rust treatment at the back of sheet metal part

BW-001