Page 355 - Six Sigma Advanced Tools for Black Belts and Master Black Belts

P. 355

OTE/SPH

OTE/SPH

August 31, 2006

Char Count= 0

3:7

JWBK119-21

340 Establishing Cumulative Conformance Count Charts

Constructing CCC

Chart

Specify

ARL

0

Obtain φ from

(21.18) and Yes Known p ?

0

γ φ (21.4)

No

Start plotting using

control limits from

(21.5) and (21.6) Estimation of p using No Estimation of p 0

0

with respective sequential estimation from conventional estimator

f and γ (21.9)? from (21.14)

f

Yes

Obtain the respective

values of φ and γ

Obtain the n φn

respective values from (21.15)

of φ and γ from and (21.4)

m φm

Table 21.2

Specify ρ and

Specify ρ and determine the value

Keep updating the determine the value of R and obtain the

c

estimate and No Is the point within the of R and obtain the minimum number of

s

control limits as m warning zone? respective m* samples needed, n*

increases

Yes

Start plotting using Start plotting using

Updating is suspended control limits from control limits from

and process monitoring is (21.10) and (21.16) and (21.17)

continued with current No (21.11) with respective with respective

control limits φ and γ φm φ and γ φn

m

n

New estimate is

initiated and

compared with the Is m > m* ? Keep updating the

suspended Is n > n* ? No estimate and

estimate control limits as n

increases

Yes

Stop updating,

Process restarted No Is there significant continue with the Yes

with new estimate difference between 2 process monitoring

estimates? using current control

limits

Yes

Combine the data

and proceed with

updating

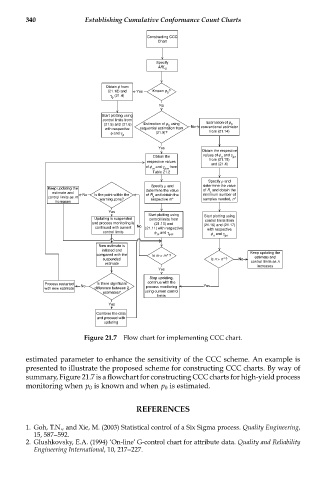

Figure 21.7 Flow chart for implementing CCC chart.

estimated parameter to enhance the sensitivity of the CCC scheme. An example is

presented to illustrate the proposed scheme for constructing CCC charts. By way of

summary, Figure 21.7 is a flowchart for constructing CCC charts for high-yield process

monitoring when p 0 is known and when p 0 is estimated.

REFERENCES

1. Goh, T.N., and Xie, M. (2003) Statistical control of a Six Sigma process. Quality Engineering,

15, 587--592.

2. Glushkovsky, E.A. (1994) ‘On-line’ G-control chart for attribute data. Quality and Reliability

Engineering International, 10, 217--227.