Page 111 - Shroeder - Filter Systems

P. 111

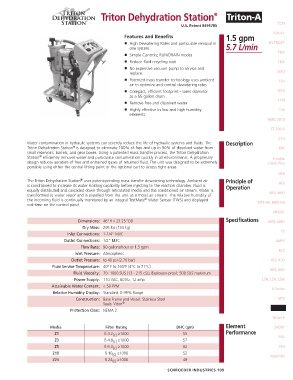

Triton Dehydration Station ® Triton-A

TCM

U.S. Patent 8491785

TCM-FC

Features and Benefits 1.5 gpm

■ High Dewatering Rates and particulate removal in HY-TRAX ®

one system 5.7 L/min

■ Simple Controls; RUN/DRAIN modes TWS

■ Reduce fluid recycling cost TMS

■ No expensive vacuum pump to service and

replace SMU

■ Patented mass transfer technology uses ambient TSU

air to optimize and control dewatering rates

■ Compact, efficient footprint - same diameter TMU

as a 55 gallon drum

TPM

■ Remove free and dissolved water

■ Highly effective in low and high humidity TIM

elements

HMG 3010

ET-100-6

CTU

Water contamination in hydraulic systems can severely reduce the life of hydraulic systems and fluids. The Description

®

Triton Dehydration Station is designed to eliminate 100% of free and up to 90% of dissolved water from EPK

small reservoirs, barrels, and gear boxes. Using a patented mass transfer process, the Triton Dehydration

®

Station efficiently removes water and particulate contamination quickly in all environments. A proprietary Trouble

design reduces aeration of free and entrained gases of returned fluid. The unit was designed to be extremely Check Plus

portable using either the central lifting point or the optional cart to access tight areas.

HTB

®

The Triton Dehydration Station uses patent-pending mass transfer dewatering technology. Ambient air Principle of HFS

is conditioned to increase its water holding capability before injecting to the reaction chamber. Fluid is Operation

equally distributed and cascaded down through reticulated media and the conditioned air stream. Water is MFS, MFD

transformed to water vapor and is expelled from the unit as a moist air stream. The relative humidity of

®

the incoming fluid is continually monitored by an integral TestMate Water Sensor (TWS) and displayed MFS-HV, MFD-HV

real-time on the control panel.

MFDBC

Dimensions: 46”H x 23.25”OD Specifications AMS, AMD

Dry Mass: 295 lbs (134 kg)

FS

Inlet Connections: 1-1/4” MJIC

Outlet Connections: 1/2” MJIC AMFS

Flow Rate: 90 gallons/hour or 1.5 gpm

KLC

Inlet Pressure: Atmospheric

Outlet Pressure: to 40 psi (2.76 bar) KLS, KLD

Fluid Service Temperature: 40° F to 160°F (4°C to 71°C)

AKS, AKD

Fluid Viscosity: 70- 1000 SUS (13 - 215 cSt), Explosion-proof: 500 SUS maximum

Power Supply: 110 VAC, 60 Hz, 12 amp LSN, LSA, LSW

Attainable Water Content: < 50 PPM

X Series

Relative Humidity Display: Standard, 0-99% Range

Construction: Base Frame and Vessel: Stainless Steel MTS

Seals: Viton ®

Triton-A

Protection Class: NEMA 2

Triton-E

Media Filter Rating DHC (gm) Element SVD01

Z1 ß 4.2 ≥1000 55 Performance SVD

(c)

Z3 ß 4.8 ≥1000 57

(c)

Z5 ß 6.3 ≥1000 62 IXU

(c)

Z10 ß 10 ≥1000 52 Appendix

(c)

Z25 ß 24 ≥1000 48

(c)

SCHROEDER INDUSTRIES

SCHROEDER INDUSTRIES

SCHROEDER INDUSTRIES 109 109 109