Page 20 - Shroeder - Filter Systems

P. 20

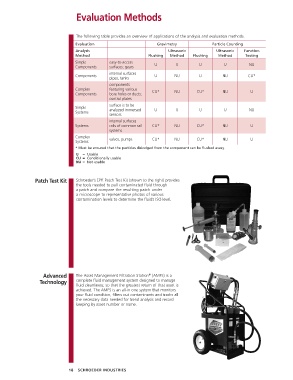

Evaluation Methods

The following table provides an overview of applications of the analysis and evaluation methods.

Evaluation Gravimetry Particle Counting

Analysis Ultrasonic Ultrasonic Function

Method Flushing Method Flushing Method Testing

Simple easy-to-access U U U U NU

Components surfaces; gears

internal surfaces

Components U NU U NU CU*

pipes, tanks

components

Complex featuring various CU* NU CU* NU U

Components bore holes or ducts;

control plates

surface is to be

Simple analyzed immersed U U U U NU

Systems

sensors

internal surfaces

Systems rails of common rail CU* NU CU* NU U

systems

Complex valves, pumps CU* NU CU* NU U

Systems

* Must be ensured that the particles dislodged from the component can be flushed away.

U = Usable

CU = Conditionally usable

NU = Not usable

Patch Test Kit Schroeder’s EPK Patch Test Kit (shown to the right) provides

the tools needed to pull contaminated fluid through

a patch and compare the resulting patch under

a microscope to representative photos of various

contamination levels to determine the fluid’s ISO level.

Advanced The Asset Management Filtration Station (AMFS) is a

®

Technology complete fluid management system designed to manage

fluid cleanliness, so that the greatest return of that asset is

achieved. The AMFS is an all-in one system that monitors

your fluid condition, filters out contaminants and tracks all

the necessary data needed for trend analysis and record

keeping by asset number or name.

18 SCHROEDER INDUSTRIES