Page 19 - Shroeder - Filter Systems

P. 19

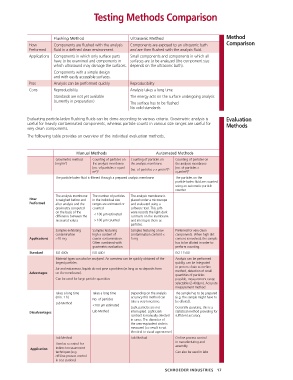

Testing Methods Comparison

Flushing Method Ultrasonic Method Method

How Components are flushed with the analysis Components are exposed to an ultrasonic bath Comparison

Preformed fluid in a defined clean environment. and are then flushed with the analysis fluid.

Applications Components in which only surface parts Small components and components in which all

have to be examined and components in surfaces are to be analyzed (the component size

which ultrasound may damage the surfaces. depends on the ultrasonic bath).

Components with a simple design

and with easily accessible surfaces.

Pros Analysis can be performed quickly Reproducibility

Cons Reproducibility Analysis takes a long time

Standards are not yet available The energy acts on the surface undergoing analysis

(currently in preparation) The surface has to be flushed

No valid standards

Evaluating particle-laden flushing fluids can be done according to various criteria. Gravimetric analysis is Evaluation

useful for heavily contaminated components, whereas particle counts in various size ranges are useful for Methods

very clean components.

The following table provides an overview of the individual evaluation methods.

Manual Methods Automated Methods

Gravimetric method Counting of particles on Counting of particles on Counting of particles on

[mg/m 2 ] the analysis membrane the analysis membrane the analysis membrane

[no. of particles > x µm/ [no. of particles > x µm/m 2 ]* [no. of particles >

m 2 ]* x µm/m 2 ]*

The particle-laden fluid is filtered through a prepared analysis membrane The particles on the

particle-laden fluid are counted

using an automatic particle

counter

The analysis membrane The number of particles The analysis membrane is

How is weighed before and in the individual size placed under a microscope

Performed after analysis and the ranges are estimated or and evaluated using a

gravimetry computed counted software tool. This soft-

on the basis of the < 100 µm estimated ware records the light-dark

difference between the contrasts on the membrane

measured values > 100 µm counted and interrupts them as

particles.

Samples exhibiting Samples featuring Samples featuring a low Preferred for very clean

contamination high a content of contamination content < components. When high dirt

Applications >10 mg coarse contamination. 5 mg content is involved, the sample

Often combined with has to be diluted in order to

gravimetric evaluation. perform counting.

Standard ISO 4405 ISO 4407 ISO 11500

Material types can also be analyzed. An overview can be quickly obtained of the Analysis can be performed

largest particles. quickly, can be integrated

in process chain as on-line

Air and extraneous liquids do not pose a problem (as long as no deposits form

Advantages on the membrane). method, detection of small

quantities of particles

Can be used for large particle quantities possible, measurement range

selectable (2-400µm). Accurate

measurement method

Takes a long time Takes a long time Depending on the analysis The sample has to be prepared

(min. 1 h) accuracy this method can (e.g. the sample might have to

No. of particles

Lab Method take a very long time. be diluted).

<100 µm estimated

Light particles are not Generally speaking, this is a

Disadvantages Lab Method interrupted. Light-Dark statistical method providing for

contrast is manually selected sufficient accuracy.

in cases. The diameter of

the area-equivalent circle is

measured (=> result is not

identical to visual appearance)

Lab Method Lab Method On-line process control

in manufacturing and

Used as a control for assembly.

Application indirect measurement

techniques (e.g. Can also be used in labs

off-line process control

in test stations)

SCHROEDER INDUSTRIES 17