Page 22 - Shroeder - Filter Systems

P. 22

Analyzing the Data

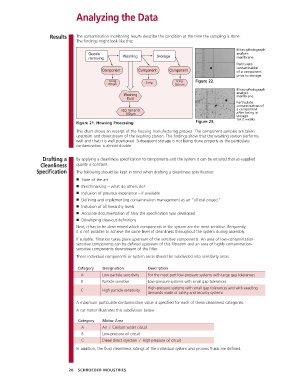

Results The contamination monitoring results describe the condition at the time the sampling is done.

The findings might look like this:

Micro-photograph

analysis

membrane

Particulate

contamination

of a component

prior to storage

5 mg 9 mg Figure 22.

300 um

Micro-photograph

analysis

membrane

Particulate

contamination of

a component

after being in

storage

Figure 21. Housing Processing Figure 23. for 2 weeks

This chart shows an excerpt of the housing manufacturing process. The component samples are taken

upstream and downstream of the washing station. The findings show that the washing station performs

well and that it is well positioned. Subsequent storage is not being done properly as the particulate

contamination is almost double.

Drafting a By applying a cleanliness specification to components and the system it can be ensured that as-supplied

Cleanliness quality is constant.

Specification The following should be kept in mind when drafting a cleanliness specification:

■ State of the art

■ Benchmarking – what do others do?

■ Inclusion of previous experience – if available

■ Defining and implementing contamination management as an “official project”

■ Inclusion of all hierarchy levels

■ Accurate documentation of how the specification was developed

■ Developing clear-cut definitions

Next, it has to be determined which components in the system are the most sensitive. Frequently,

it is not possible to achieve the same level of cleanliness throughout the system during assembly.

If suitable, filtration takes place upstream of the sensitive components. An area of low-contamination-

sensitive components can be defined upstream of this filtration and an area of highly contamination-

sensitive components downstream of the filter.

These individual components or system areas should be subdivided into sensitivity areas.

Category Designation Description

A Low particle-sensitivity For the most part low-pressure systems with large gap tolerances

B Particle-sensitive Low-pressure systems with small gap tolerances

High-pressure systems with small gap tolerances and with exacting

C High particle sensitivity

demands made of safety and security systems

A maximum particulate contamination value is specified for each of these cleanliness categories.

A car motor illustrates this subdivision below:

Category Motor Area

A Air / Coolant water circuit

B Low-pressure oil circuit

C Diesel direct injection / High-pressure oil circuit

In addition, the fluid cleanliness ratings of the individual system and process fluids are defined.

20 SCHROEDER INDUSTRIES