Page 30 - Flip IOCL Book.cdr

P. 30

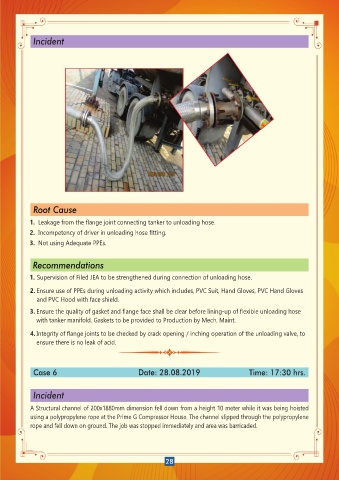

Incident

Root Cause

1. Leakage from the flange joint connecting tanker to unloading hose.

2. Incompetency of driver in unloading hose fitting.

3. Not using Adequate PPEs.

Recommendations

1. Supervision of Filed JEA to be strengthened during connection of unloading hose.

2. Ensure use of PPEs during unloading activity which includes, PVC Suit, Hand Gloves, PVC Hand Gloves

and PVC Hood with face shield.

3. Ensure the quality of gasket and flange face shall be clear before lining-up of flexible unloading hose

with tanker manifold. Gaskets to be provided to Production by Mech. Maint.

4. Integrity of flange joints to be checked by crack opening / inching operation of the unloading valve, to

ensure there is no leak of acid.

Case 6 Date: 28.08.2019 Time: 17:30 hrs.

Incident

A Structural channel of 200x1880mm dimension fell down from a height 10 meter while it was being hoisted

using a polypropylene rope at the Prime G Compressor House. The channel slipped through the polypropylene

rope and fell down on ground. The job was stopped immediately and area was barricaded.

28