Page 66 - Towards A Sustainable Future , Phase 3 2025, E-Book_Neat

P. 66

Good Environmental Practices

EcoPlus Manufacturing adopts environmentally conscious For a typical HPL sheet with dimensions 1830 x 3660mm x

practices within its business operations. High-pressure 12mm, the volume is (1.83 x 3.66 x 0.012) m3 with a weight

Laminates (HPL) sheets are sourced from eco-friendly of 113 kg. The cost price for a typical HPL sheet is about $400.

companies like Formica and Greenlam, reputed companies (Annexe A, Environmental Review)

that adopt forest stewardship initiatives and are leaders in the

Singapore Green Building Product (SGBP) certification. Recycled Kraft papers are the main component (70%) in the

laminated sheet, which includes the décor and overlay papers,

Besides that, EcoPlus Manufacturing also adopts the 3 Rs an overall 80% while the remaining components (20%) will be

(Reduce, Reuse and Recycle) initiatives on its waste, the the recycled phenolic and melamine resins. A carbon emission

phenolic dust and powder (phenolic formaldehyde resin factor of 0.942 kg CO2/kg (paper) will be used since recycled

powder) that are sucked by vacuum pumps to be stored into Kraft papers are the main components, while carbon emission

bags, further recycled for the curing and toughening of the factors for the recycled resins will not be considered.

paper honeycomb panels used in EcoPlus's Favolic Design.

The monthly consumption of HPL sheets for all 10 model

EcoPlus Manufacturing also hires a local certified waste designs in the toilet cubicle solutions averages about 200

disposal company, Energy 21 Pte Ltd, to dispose of the smaller sheets (20 x 10). The total monthly weight is about 22600 kg

off-cuts derived from the HPL sheets. At the same time, the (20 x 10 x 113) in Table 2, which leads to an annual carbon

bigger off-cuts are used for other projects when needed. emission of 255470.4 kilograms of carbon emission factor of

Ecoplus is reconsidering waste management for the smaller 0.942 kg CO2/kg (paper) in Table 3. The yearly total carbon

off-cuts (quantity average monthly about 0.3 tonnes) to move emission for EcoPlus is 306846.9 kg. (Annexe A, Environmental

towards a circular model approach. Review)

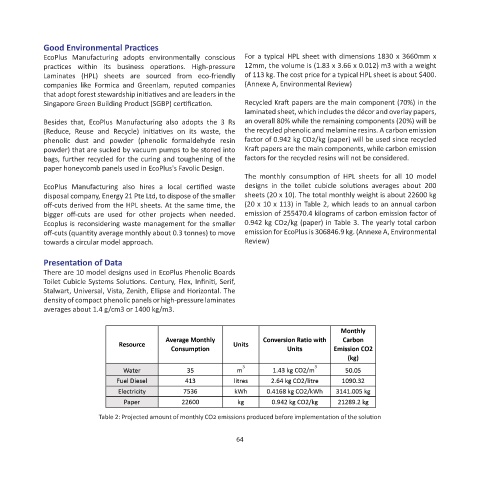

Presentation of Data

There are 10 model designs used in EcoPlus Phenolic Boards

Toilet Cubicle Systems Solutions. Century, Flex, Infiniti, Serif,

Stalwart, Universal, Vista, Zenith, Ellipse and Horizontal. The

density of compact phenolic panels or high-pressure laminates

averages about 1.4 g/cm3 or 1400 kg/m3.

Table 2: Projected amount of monthly CO2 emissions produced before implementation of the solution

64