Page 35 - Gi February 2022

P. 35

igem news – yppc

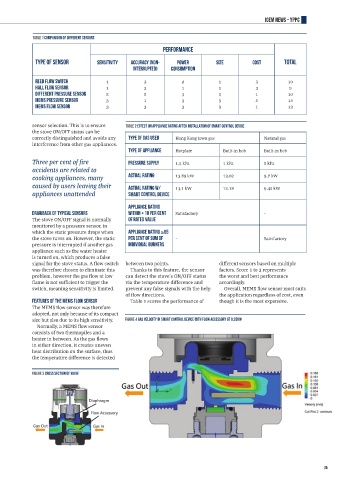

TABLE 1 COMPARISON OF DIFFERENT SENSORS

performance

type of sensor sensitivity accuracy (non- power size cost total

interrupted) consumption

reed flow switch 1 3 2 1 3 10

hall flow sensor 1 3 1 1 3 9

different pressure sensor 2 2 3 2 1 10

mems pressure sensor 3 1 3 3 2 12

mems flow sensor 3 3 3 3 1 13

sensor selection. This is to ensure TABLE 2 EFFECT ON APPLIANCE RATING AFTER INSTALLATION OF SMART CONTROL DEVICE

the stove ON/OFF status can be

correctly distinguished and avoids any type of gas used Hong Kong town gas Natural gas

interference from other gas appliances.

type of appliance Hotplate Built-in hob Built-in hob

Three per cent of fire pressure supply 1.5 kPa 1 kPa 2 kPa

accidents are related to

cooking appliances, many actual rating 13.89 kW 13.02 9.7 kW

caused by users leaving their actual rating w/ 13.1 kW 12.18 9.42 kW

appliances unattended smart control device

Appliance rating

Drawback of typical sensors within ± 10 per cent Satisfactory –

The stove ON/OFF signal is normally of rated value

monitored by a pressure sensor, in

which the static pressure drops when Appliance Rating ≥85

the stove turns on. However, the static per cent of sum of – Satisfactory

pressure is interrupted if another gas individual burners

appliance such as the water heater

is turned on, which produces a false

signal for the stove status. A flow switch between two points. different sensors based on multiple

was therefore chosen to eliminate this Thanks to this feature, the sensor factors. Score 1 to 3 represents

problem, however the gas flow at low can detect the stove’s ON/OFF status the worst and best performance

flame is not sufficient to trigger the via the temperature difference and accordingly.

switch, meaning sensitivity is limited. prevent any false signals with the help Overall, MEMS flow sensor most suits

of flow directions. the application regardless of cost, even

Features of the MEMS flow sensor Table 1 scores the performance of though it is the most expensive.

The MEMS flow sensor was therefore

adopted, not only because of its compact

size but also due to its high sensitivity. FIGURE 4 GAS VELOCITY IN SMART CONTROL DEVICE WITH FLOW ACCESSORY AT 0.25KW

Normally, a MEMS flow sensor

consists of two thermopiles and a

heater in between. As the gas flows

in either direction, it creates uneven

heat distribution on the surface, thus

the temperature difference is detected

FIGURE 3 CROSS SECTION OF VALVE

35

27/01/2022 14:24

IGEMNews_YPPC.indd 2

IGEMNews_YPPC.indd 2 27/01/2022 14:24