Page 93 - PIGNAT catalogue 2020 GB_092020

P. 93

PURIFIED WATER

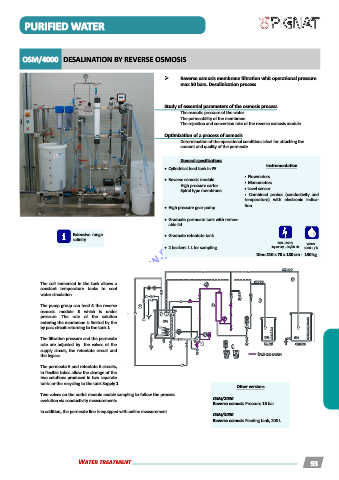

OSM/4000 DESALINATION BY REVERSE OSMOSIS

➢ Reverse osmosis membrane filtration whit operational pressure

max 50 bars. Desalinization process

Study of essential parameters of the osmosis process

The osmotic pressure of the water

The permeability of the membrane

The rejection and conversion rate of the reverse osmosis module

Optimization of a process of osmosis

Determination of the operational conditions ideal for attaching the

amount and quality of the permeate

General specifications

Instrumentation

• Cylindrical feed tank in PE.

• Flowmeters.

• Reverse osmosis module • Manometers.

High pressure carter. • Level sensor.

Spiral type membrane • Combined probes (conductivity and

• High pressure gear pump. temperature) with electronic indica-

tion.

www.pignat.com 1ϕ or 3ϕ - 50/60 Hz 1000 L / h

able lid.

Extensive range • Graduate permeate tank with remov-

• Graduate retentate tank.

salinity www.pignat.com

200 - 240 V

Water

• 2 beakers 1 L for sampling.

Dim: 210 x 70 x 180 cm - 150 kg

6

The coil immersed in the tank allows a

constant temperature tanks to cool

water circulation.

5

The pump group can feed 4 the reverse 2 3

osmosis module 3 which is under

pressure. The rate of the solution

entering the membrane is limited by the

by pass circuit returning to the tank 1.

The filtration pressure and the permeate 1

rate are adjusted by the valves of the 4

supply circuit, the retentate circuit and 8

the bypass.

7

The permeate 5 and retentate 6 circuits,

in flexible tubes allow the storage of the

two solutions produced in two separate

tanks or the recycling to the tank Supply 1.

Other versions

Two valves on the outlet module enable sampling to follow the process

evolution via conductivity measurements. OSM/2000

Reverse osmosis Pressure 16 bar

In addition, the permeate line is equipped with online measurement.

OSM/3000

Reverse osmosis Feeding tank, 200 L

Water treatment 93