Page 140 - Buy Premium Tools ATORN Catalogue

P. 140

Tools for threads

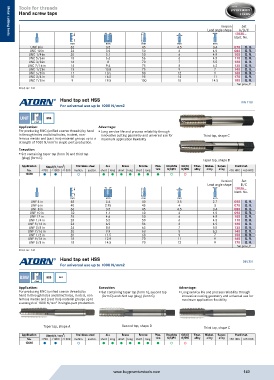

Hand screw taps

Version Set

Lead angle shape A/D/C

13030...

Ident. No.

Metal cutting tools

Metal cutting tools

mm mm mm mm mm

UNC 8 in 32 3.5 45 4.5 3.4 070 O. R.

UNC 10 in 24 3.9 50 6 4.9 080 O. R.

UNC 1/4 in 20 5.1 50 6 4.9 100 O. R.

UNC 5/6 in 18 6.6 56 6 4.9 110 O. R.

UNC 3/8 in 16 8 70 7 5.5 120 O. R.

UNC 7/16 in 14 9.4 75 8 6.2 130 O. R.

UNC 1/2 in 13 10.8 75 9 7 140 O. R.

UNC 5/8 in 11 13.5 80 12 9 160 O. R.

UNC 3/4 in 10 16.5 95 14 11 170 O. R.

UNC 7/8 in 9 19.5 100 18 14.5 180 O. R.

Set price, €

Prod. Gr. 131

Hand tap set HSS

For universal use up to 1000 N/mm2 DIN 2181

UNF HSS

3xd

Application: Advantage:

For producing UNC (unified coarse threads) by hand Long service life and process reliability through

in through holes and blind holes, in steel, non- innovative cutting geometry and universal use for Third tap, shape C

ferrous metals and (cast iron) material groups up to a maximum application flexibility

strength of 1000 N/mm in single-part production.

2

Execution:

Set containing taper tap (form D) and third tap

(plug) (form C)

Taper tap, shape D

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13035

Version Set

Lead angle shape D/C

13035...

Ident. No.

mm mm mm mm mm

UNF 4 in 48 2.4 40 3.5 2.7 050 O. R.

UNF 6 in 40 2.95 45 4 3 070 O. R.

UNF 8 in 36 3.5 45 4.5 3.4 080 O. R.

UNF 10 in 32 4.1 50 6 4.9 090 O. R.

UNF 12 in 28 4.6 50 6 4.9 100 O. R.

UNF 1/4 in 28 5.5 50 6 4.9 110 O. R.

UNF 5/16 in 24 6.9 56 6 4.9 120 O. R.

UNF 3/8 in 24 8.5 63 7 5.5 130 O. R.

UNF 7/16 in 20 9.9 63 8 6.2 140 O. R.

UNF 1/2 in 20 11.5 63 9 7 150 O. R.

UNF 9/16 in 18 12.9 70 11 9 160 O. R.

UNF 5/8 in 18 14.5 70 12 9 170 O. R.

Set price, €

Prod. Gr. 131

Hand tap set HSS DIN 351

For universal use up to 1000 N/mm2

BSW HSS

3xd

Application: Execution: Advantage:

For producing UNC (unified coarse threads) by Set containing taper tap (form A), second tap Long service life and process reliability through

hand in through holes and blind holes, in steel, non- (form D) and third tap (plug) (form C) innovative cutting geometry and universal use for

ferrous metals and (cast iron) material groups up to maximum application flexibility

a strength of 1000 N/mm in single-part production.

2

Taper tap, shape A Second tap, shape D Third tap, shape C

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13040

www.buypremiumtools.com 140