Page 278 - Buy Premium Tools ATORN Catalogue

P. 278

Milling tools

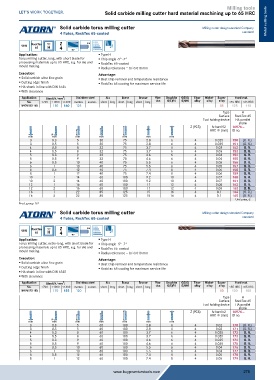

Solid carbide milling cutter hard material machining up to 65 HRC

Solid carbide torus milling cutter Milling cutter design standard Company Metal cutting tools

4 flutes, RockTec 65-coated standard

RockTec Typ Z HA

VHM H

65 4

Application: Type H

Torus milling cutter, long, with short blade for Chip angle -5° -7°

processing materials up to 65 HRC, e.g. for die and RockTec 65-coated

mould making.

Radius tolerance = 0/-0.010 mm

Execution: Advantage:

Solid carbide ultra-fine grain Best chip removal and temperature resistance

Cutting edge finish RockTec 65 coating for maximum service life

HA shank in line with DIN 6535

With clearance

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16976150-165 180 160 125 85 125 110

Type H

Surface RockTec 65

Tool holding device HA parallel

shank

Z (PCS) fz hard 52 16976...

HRC (mm) ID no.

mm mm mm mm mm mm mm

3 0.3 5 30 75 2.8 6 4 0.025 150 (O. R.)

3 0.5 5 30 75 2.8 6 4 0.025 151 (O. R.)

4 0.3 8 32 75 3.7 6 4 0.03 152 O. R.

4 0.5 8 32 75 3.7 6 4 0.03 153 O. R.

5 0.3 9 32 75 4.6 6 4 0.04 154 O. R.

5 0.5 9 32 75 4.6 6 4 0.04 155 O. R.

6 0.5 10 40 75 5.5 6 4 0.05 156 O. R.

6 1 10 40 75 5.5 6 4 0.05 157 O. R.

8 0.5 12 40 75 7.4 8 4 0.06 158 O. R.

8 1 12 40 75 7.4 8 4 0.06 159 O. R.

10 1 14 60 100 9.2 10 4 0.07 160 O. R.

10 2 14 60 100 9.2 10 4 0.07 161 O. R.

12 1 16 60 100 11 12 4 0.08 162 O. R.

12 2 16 60 100 11 12 4 0.08 163 O. R.

16 1 22 85 125 15 16 4 0.1 164 (O. R.)

16 2 22 85 125 15 16 4 0.1 165 (O. R.)

Unit price, €

Prod. group 152

Solid carbide torus milling cutter Milling cutter design standard Company

4 flutes, RockTec 65-coated standard

VHM RockTec Typ Z HA

H

65 4

Application: Type H

Torus milling cutter, extra-long, with short blade for Chip angle -5° -7°

processing materials up to 65 HRC, e.g. for die and RockTec 65-coated

mould making. Radius tolerance = 0/-0.010 mm

Execution: Advantage:

Solid carbide ultra-fine grain Best chip removal and temperature resistance

Cutting edge finish RockTec 65 coating for maximum service life

HA shank in line with DIN 6535

With clearance

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16976170-185 170 155 120 80 120 100

Type H

Surface RockTec 65

Tool holding device HA parallel

shank

Z (PCS) fz hard 52 16976...

HRC (mm) ID no.

mm mm mm mm mm mm mm

3 0.3 5 60 100 2.8 6 4 0.02 170 (O. R.)

3 0.5 5 60 100 2.8 6 4 0.02 171 (O. R.)

4 0.3 8 60 100 3.7 6 4 0.025 172 O. R.

4 0.5 8 60 100 3.7 6 4 0.025 173 O. R.

5 0.3 9 60 100 4.6 6 4 0.035 174 O. R.

5 0.5 9 60 100 4.6 6 4 0.035 175 O. R.

6 0.5 10 60 100 5.5 6 4 0.04 176 O. R.

6 1 10 60 100 5.5 6 4 0.04 177 O. R.

8 0.5 12 60 100 7.4 8 4 0.05 178 O. R.

8 1 12 60 100 7.4 8 4 0.05 179 O. R.

www.buypremiumtools.com 278