Page 283 - Buy Premium Tools ATORN Catalogue

P. 283

Milling tools

Cutters with indexable inserts

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat. Metal cutting tools

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16977260-268 220 200 155 105 155 130

Type H

Surface RockTec 65

Tool holding device HA parallel

shank

Z (PCS) fz hard 65 16977...

HRC (mm) ID no.

mm mm mm mm mm mm

3 5 14 50 2.8 6 4 0.025 260 O. R.

4 8 20 50 3.7 6 4 0.035 261 O. R.

5 9 20 50 4.6 6 4 0.04 262 O. R.

6 10 20 50 5.5 6 4 0.05 263 O. R.

8 12 30 64 7.4 8 4 0.07 264 O. R.

10 14 32 70 9.2 10 4 0.08 265 O. R.

12 16 38 75 11 12 4 0.09 266 O. R.

16 32 46 90 15 16 4 0.1 267 O. R.

20 38 58 100 19 20 4 0.12 268 O. R.

Unit price, €

Prod. group 152

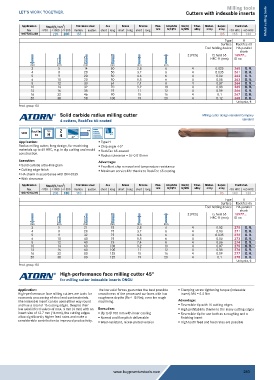

Solid carbide radius milling cutter Milling cutter design standard Company

4 cutters, RockTec 65-coated standard

VHM RockTec Typ Z HA

H

65 4

Application: Type H

Radius milling cutter, long design, for machining Chip angle -10°

materials up to 65 HRC, e.g. in dip cutting and mould RockTec 65-coated

construction. Radius tolerance = 0/-0.010 mm

Execution: Advantage:

Solid carbide ultra-fine grain Excellent chip removal and temperature resistance

Cutting edge finish Maximum service life thanks to RockTec 65 coating

HA shank in accordance with DIN 6535

With clearance

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16977270-278 200 180 140 95 140 120

Type H

Surface RockTec 65

Tool holding device HA parallel

shank

Z (PCS) fz hard 65 16977...

HRC (mm) ID no.

mm mm mm mm mm mm

3 5 21 75 2.8 6 4 0.02 270 O. R.

4 8 28 75 3.7 6 4 0.03 271 O. R.

5 9 32 75 4.6 6 4 0.035 272 O. R.

6 10 40 75 5.5 6 4 0.04 273 O. R.

8 12 40 75 7.4 8 4 0.06 274 O. R.

10 14 60 100 9.2 10 4 0.07 275 O. R.

12 16 60 100 11 12 4 0.08 276 O. R.

16 32 80 125 15 16 4 0.09 277 O. R.

20 38 80 125 19 20 4 0.1 278 O. R.

Unit price, €

Prod. group 152

High-performance face milling cutter 45°

for milling cutter indexable inserts ONGU

Application: The low axial forces guarantee the best possible Clamping screw tightening torque (indexable

High-performance face milling cutters are tools for smoothness of the processed surfaces with low insert) M4 = 5.2 Nm

economic processing of steel and cast materials. roughness depths (Rz < 15 Nm), even for rough

The indexable insert can be used either way round machining. Advantage:

and has a total of 16 cutting edges. Despite their Reversible tip with 16 cutting edges

low axial infeed values of max. 3 mm (4 mm) with an Execution: High profitability thanks to the many cutting edges

insert size of 12.7 mm (16 mm), the cutting edges Up to Ø 100 mm with inner cooling Reversible tip for use both as a roughing and a

allow significantly higher feed rates and make a Normal and fine pitch deliverable finishing insert

considerable contribution to improved productivity. Wear-resistant, nickel-plated version High tooth feed and feed rates are possible

www.buypremiumtools.com 283