Page 23 - Stanochny park

P. 23

INNOVATIVE TECHNOLOGY INNOVATIVE TECHNOLOGY

processing time on the CNC machine.

Given the complex shape and

large dimensions of the workpieces, it

was decided to scan them directly at the

customer’s enterprise using a portable

coordinate measuring machine (CMM)

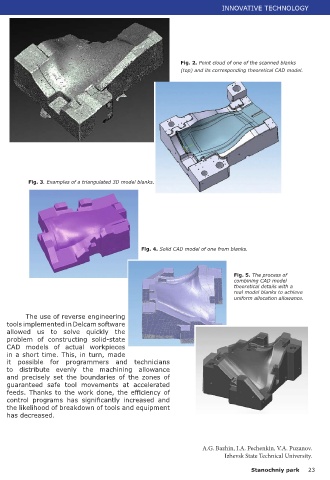

СimСore INFINITE 2.0, equipped with a Fig. 2. Point cloud of one of the scanned blanks

ScanWorks laser scanner. With its help, a (top) and its corresponding theoretical CAD model.

3D scan of three blanks was made. The

scanning process was carried out in several

KIM reinstallations necessary for access

to product elements from all sides. As a

result, up to six files were obtained for each

blank describing its shape using clouds

of scanned points in various coordinate

systems. Then, using the PowerINSPECT

CAI system (also developed by Delcam),

Fig. 3. Examples of a triangulated 3D model blanks.

Fig. 4. Solid CAD model of one from blanks.

Fig. 5. The process of

combining CAD model

theoretical details with a

real model blanks to achieve

uniform allocation allowance.

Fig. 1. Heat-resistant blank dies, The use of reverse engineering

machined on CNC machines. tools implemented in Delcam software

allowed us to solve quickly the

problem of constructing solid-state

CAD models of actual workpieces

in a short time. This, in turn, made

the files were combined into a single coordinate system. Figure 2 shows the result of scanning it possible for programmers and technicians

in the form of point clouds (above) and the theoretical CAD-model of the workpiece, constructed to distribute evenly the machining allowance

according to the design documentation. After processing the scanned data in PowerSHAPE Pro and precisely set the boundaries of the zones of

(removing unnecessary and obviously erroneous points, thinning and smoothing surfaces), guaranteed safe tool movements at accelerated

triangulated 3D models of actual workpieces were constructed (Fig. 3). feeds. Thanks to the work done, the efficiency of

In order for the obtained 3D models of actual workpieces to be used in the CAM system control programs has significantly increased and

used at the enterprise, PowerSHAPE Pro also needed to create traditional solid-state CAD models the likelihood of breakdown of tools and equipment

of workpieces with an exact mathematical description based on triangulated surfaces (Fig. 4). has decreased.

In addition, auxiliary planes were constructed, which serve to base the theoretical CAD model

of the part relative to the actual workpiece.

After constructing solid-state CAD models of real workpieces, each CAD model of the

theoretical part was combined with a real workpiece model based on the condition of ensuring

the most uniform machining allowance (Fig. 5). A.G. Bazhin, I.A. Pechenkin, V.A. Puzanov.

Izhevsk State Technical University.

22 Stanochniy park Stanochniy park 23