Page 7 - TWIMS Posters 2023

P. 7

SHAPING LEAN TEACHING BACKGROUND FINDINGS

METHODS: The effectiveness of lean teaching methods at a post graduate level has been widely documented by various The findings related to the most significant TWIMS teaching approaches that change students’

authors over the last few years. This has shaped the teaching methods adopted by practitioners globally in

perspectives of lean are illustrated in Figure 2. A critical finding was that “interaction with fellow

ensuring that these lean methods and concepts, with their associated learnings, secure effective pragmatic

class participants” was the most frequently cited element that changed students’ perspectives on

comprehension within manufacturing environments. A key consideration is: have these teaching methods

been successful in representing lean as a system underpinned by a long-term management philosophy, or lean. This is likely due to a healthy balance of different manufacturing sectors and backgrounds

represented by students within the class. The value of practical firm level examples was the second

has it rather encouraged the view that lean is a set of practices or tools?

RECOGNIZING LEAN AS A Lean manufacturing has typically been presented by academics, practitioners and consultants as a set of most frequently cited teaching approach, again highlighting the value attached to the exposure to

different industries.

practices and methods, that if integrated correctly into processes and ways of working, will yield positive

business results. These results emerge because of reduced waste and improved flow of communication, Due to COVID-19 not all students were able to participate in a factory visit. Thus, “factory visits”

would likely have been more frequently cited. Of those students who did attend factory visits,

material, information and movements within a value chain (Womack and Jones 2003). Authors such as Liker

JOURNEY VS. A SET OF TOOLS (2021), Bhasin and Burcher (2006) and Ballé et al (2015), have postulated that lean goes far beyond those personal interactions showed this immersive learning experience to be particularly profound.

practices and has to be viewed as a philosophy, integrated as a part of broader management culture and

Figure 2 also showed “lean games” to be frequently cited, emphasising the value of interactive and

strategy. Only 10% of organizations link the philosophy element to lean as part of the company culture, which

may explain why only 10% of lean transformation journeys are successful or sustained (Bhasin and Burcher experiential exercises for effective transformative teaching methods for lean implementation.

2006; Poksinska et al. 2013).

Whilst the review of teaching methods has been encouraged by the lean academic community, the critical

question is whether these teaching methods are adequate in shifting the wrongful assumptions of lean by

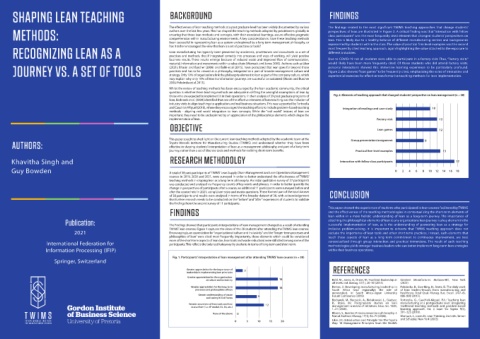

those who are expected to implement it in their operations. In their analysis of 39 post graduate programs of Fig. 2. Elements of teaching approach that changed students’ perspective on lean management (n = 38)

lean, Bednarek et al. (2020) identified that one of the effective elements of lean teaching was the inclusion of

industry visits to align teachings to application and real business situations. This was supported by Tortorella

and Cauchick-Miguel (2018), where they encouraged the teaching efforts to include problem-based teaching Integration of readings and case study 10

methods - aligning real world integration to lean concepts. While the “real world” lessons of lean are

important, they need to be underpinned by an appreciation of the philosophical elements which shape the

implementation of lean. Factory visit 12

OBJECTIVE Lean games 12

This paper sought to shed light on the current lean teaching methods adopted by the academic team at the Group presentation/assignment 8

AUTHORS: Toyota Wessels institute for Manufacturing Studies (TWIMS) and understand whether they have been

effective in shaping students’ interpretation of lean as a management philosophy and part of a long-term

journey, rather than a set of discrete tools and methods for realizing short-term benefits. Practical firm level examples 13

Khavitha Singh and RESEARCH METHODOLGY Interaction with fellow class participants 17

Guy Bowden A total of 38 past participants of TWIMS’ Lean Supply Chain Management and Lean Operations Management 0 2 4 6 8 10 12 14 16 18

courses in 2019, 2020 and 2021, were surveyed in order to better understand the effectiveness of TWIMS’

teaching methods in shaping lean as a long-term philosophy. An initial qualitative survey of 27 participants

was conducted and analysed via frequency counts of key words and phrases. In order to better quantify the

change in perspectives of participants after a course, an additional 11 participants were surveyed before and

after the course held in 2021, using Likert-style and matrix questions. These formed part of the total dataset

of 38 participants and results were analysed in terms of the broader dataset of 38, with acknowledgement CONCLUSION

that further research needs to be conducted on the “before” and “after” experiences of students to validate

the findings from the second survey of 11 participants.

FINDINGS This paper showed the experiences of students who participated in lean courses facilitated by TWIMS

and the effectiveness of the teaching methodologies in contextualizing the short-term elements of

lean within in a more holistic understanding of lean as a long-term journey. The importance of

Publication: The findings showed that participants interpretations of lean management changed as a result of attending attaching the philosophical elements of lean to any organizations lean journey is a key element in the

successful implementation of lean, as is the understanding of promoting lean as a strategy for

TWIMS’ lean courses. Figure 1 captures the views of the 38 students after attending the TWIMS lean courses. inclusive problem-solving. It is important to reiterate that TWIMS teaching approach does not

2021 Encouragingly, an appreciation for “organizational culture and inclusivity” and the “longer-term processes and exclude the importance of lean tools and other short-term practices. Instead, such elements that

philosophies of lean” were cited most frequently. Importantly, those elements which could be considered teach these aspects of lean as a long term commitment to continuous improvement, are best

more of the short-term aspects of lean (i.e., lean tools and waste reduction) were still cited among some of the contextualized through group interaction and practical immersions. The result of such teaching

International Federation for participants. This reflects the balanced takeaway by students in terms of long-term and short-term. methodologies yields stronger business leaders who can better implement long-term lean strategies

Information Processing (IFIP) within their business operations.

Fig. 1. Participants’ interpretation of lean management after attending TWIMS’ lean courses (n = 38)

Springer, Switzerland

Greater appreciation for the importance of 3 REFERENCES

leadership in implementing lean principles

Greater appreciation for the organisation-

al culture and inclusivity 18 Ballé, M., Jones, D., Orzen, M.: True lean leadership at Greatest Manufacturer. McGraw-Hill, New York

all levels. Ind. Manag. 57(1), 26–30 (2015) (2021)

Greater appreciation for the long-term 18 Barnes, J.: Developing manufacturing leadership in Poksinska, B., Swartling, D., Drotz, E.: The daily work

processes and philosophies of lean South Africa (and regionally): the role of of lean leaders–lessons from manufacturing and

monozukuri. In: South Africa–Japan University healthcare. Total Qual. Manag. Bus. Excell. 24(7–8),

Greater understanding of waste 9 Forum Conference (2019) 886–898 (2013).

and seeing it in all forms

Bednarek, M., Buczacki, A., Bielakowski, L., Gladysz, Tortorella, G., Cauchick-Miguel, P.A.: Teaching lean

B., Bryke, M.: Postgraduate studies on lean manufacturing at a postgraduate level: integrating

Greater awareness of lean tools and how 12

to use them (i.e. 4P model, 55, 3A, etc.) management–a review of initiatives. Educ. Sci. 10(8), traditional teaching methods and problem-based

1–21 (2020). learning approach. Int. J. Lean Six Sigma 9(3),

None of the above 0 Bhasin, S., Burcher, P.: Lean viewed as a philosophy. J. 301–323 (2018).

Manuf. Technol. Manag. 17(1), 56–72 (2006). Womack, J., Jones D.: Lean Thinking. 2nd edn. Simon

0 5 10 15 20 Liker, J.K.: Introduction and Principle 1 in The Toyota and Schuster, New York (2003)

Way: 14 Management Principles from the World’s