Page 6 - TWIMS Posters 2023

P. 6

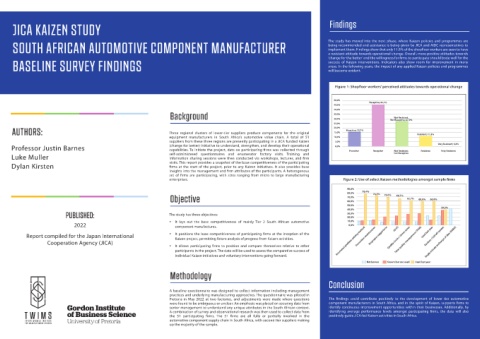

JICA KAIZEN STUDY Findings

SOUTH AFRICAN AUTOMOTIVE COMPONENT MANUFACTURER The study has moved into the next phase, where Kaizen policies and programmes are

being recommended and assistance is being given by JICA and AIDC representatives to

implement them. Findings show that only 11.8% of the shopfloor workers are seen to have

a resistant attitude towards operational change. Overall, more positive attitudes towards

BASELINE SURVEY FINDINGS ‘change for the better’ and the willingness for firms to participate should bode well for the

success of Kaizen interventions. Indicators also show room for improvement in many

areas. In the following years, the impact of any applied Kaizen policies and programmes

will become evident.

Figure 1: Shopfloor workers’ perceived attitudes towards operational change

50,0%

Receptive; 45,1%

45,0%

40,0%

Background 35,0% Not Resistant,

30,0%

25,0% Nor Receptive; 27,5%

AUTHORS: Three regional clusters of lower-tier suppliers produce components for the original 20,0% Proactive; 15,7%

15,0%

equipment manufacturers in South Africa’s automotive value chain. A total of 51 10,0% Resistant; 11,8%

suppliers from these three regions are presently participating in a JICA funded Kaizen 5,0% Very Resistant; 0,0%

Professor Justin Barnes (change for better) initiative to understand, strengthen, and develop their operational 0,0% Proactive Receptive Not Resistant; Resistant Very Resistant

capabilities. To initiate the project, data on participating firms was collected through

Luke Muller self-administered questionnaires and enumerator factory visits. Training and Nor Receptive

information sharing sessions were then conducted via workshops, lectures, and firm

visits. This report provides a snapshot of the base competitiveness of the participating

Dylan Kirsten firms at the start of the project, prior to any Kaizen initiatives. It also provides base

insights into the management and firm attributes of the participants. A heterogenous

set of firms are participating, with sizes ranging from micro to large manufacturing

enterprises. Figure 2: Use of select Kaizen methodologies amongst sample firms

90,0%

78,4%

80,0% 74,5% 70,6%

Objective 70,0% 66,7% 62,7% 60,8% 60,8%

60,0%

50,0%

39,2%

40,0%

PUBLISHED: The study has three objectives: 30,0%

20,0%

It lays out the base competitiveness of mainly Tier 2 South African automotive 10,0%

2022 component manufactures. 0,0% 4S/5S

Employee suggestions

Kanban / Call off system

Report compiled for the Japan International It positions the base competitiveness of participating firms at the inception of the Prevention maintenance Quality circles / Green areas Used last year

Kaizen project, permitting future analysis of progress from Kaizen activities.

Cooperation Agency (JICA) Structured problem-solving method Total quality management (TOM) Single minute exchange of dies (SMED)

It allows participating firms to position and compare themselves relative to other

participants in the project. The data will be used to assess the comparative success of

individual Kaizen initiatives and voluntary interventions going forward.

Not known Known but not used Used last year

Methodology

Conclusion

A baseline questionnaire was designed to collect information including management

practices and underlying manufacturing approaches. The questionnaire was piloted in

Pretoria in May 2022 at two factories, and adjustments were made where questions The findings could contribute positively to the development of lower tier automotive

were found to be ambiguous or unclear. An emphasis was placed on securing data from component manufacturers in South Africa, and in the spirit of Kaizen, supports firms to

senior management to understand any unique attributes in the South African context. identify continuous improvement opportunities within their businesses. Additionally, by

A combination of survey and observational research was then used to collect data from identifying average performance levels amongst participating firms, the data will also

the 51 participating firms. The 51 firms are all fully or partially involved in the positively guide JICA-led Kaizen activities in South Africa.

automotive component supply chain in South Africa, with second tier suppliers making

up the majority of the sample.