Page 375 - Six Sigma Advanced Tools for Black Belts and Master Black Belts

P. 375

OTE/SPH

OTE/SPH

August 31, 2006

3:8

JWBK119-23

Char Count= 0

360 Statistical Process Control for Autocorrelated Processes

Observations (Yt)

8

6

4

2

0

−2

−4

−6

−8

0 25 50 75 100 125 150 175 200 225 250 275 300

TIME (t)

2

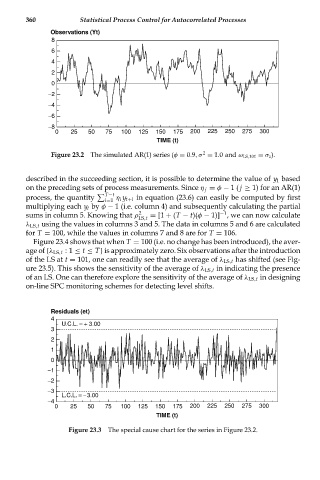

Figure 23.2 The simulated AR(1) series (φ = 0.9,σ = 1.0 and ω LS,101 = σ z ).

described in the succeeding section, it is possible to determine the value of y 1 based

on the preceding sets of process measurements. Since η j = φ − 1( j ≥ 1) for an AR(1)

T−t

process, the quantity i=1 η i y t+i in equation (23.6) can easily be computed by first

multiplying each y t by φ − 1 (i.e. column 4) and subsequently calculating the partial

−1

sums in column 5. Knowing that ρ 2 = [1 + (T − t)(φ − 1)] , we can now calculate

LS,t

λ LS,t using the values in columns 3 and 5. The data in columns 5 and 6 are calculated

for T = 100, while the values in columns 7 and 8 are for T = 106.

Figure 23.4 shows that when T = 100 (i.e. no change has been introduced), the aver-

age of {λ LS,t :1 ≤ t ≤ T} is approximately zero. Six observations after the introduction

of the LS at t = 101, one can readily see that the average of λ LS,t has shifted (see Fig-

ure 23.5). This shows the sensitivity of the average of λ LS,t in indicating the presence

of an LS. One can therefore explore the sensitivity of the average of λ LS,t in designing

on-line SPC monitoring schemes for detecting level shifts.

Residuals (et)

4

U.C.L. = + 3.00

3

2

1

0

−1

−2

−3

L.C.L. = − 3.00

−4

0 25 50 75 100 125 150 175 200 225 250 275 300

TIME (t)

Figure 23.3 The special cause chart for the series in Figure 23.2.