Page 52 - Flip IOCL Book.cdr

P. 52

Recommendations

1. Installation of additional standard Power distribution board duly certified by Electrical Maintenance.

2. Cable tray system to be extended up-to load points as feasible.

3. Road crossing with provision of proper RCC pipes.

4. Urgent removal of vegetation/debris to be removed all around substation and other areas of fabrication

yard. Proper approach to be made for vehicle movement.

5. All contractors in the fabrication yard shall comply the good housekeeping practices throughout the year.

6. Cable laying to be done in accordance with standard practice.

7. Power supply to be stopped after working hours. SOP to be made and ensured.

Case 34 Date: 03.10.2020 Time: 17:30 hrs.

Incident

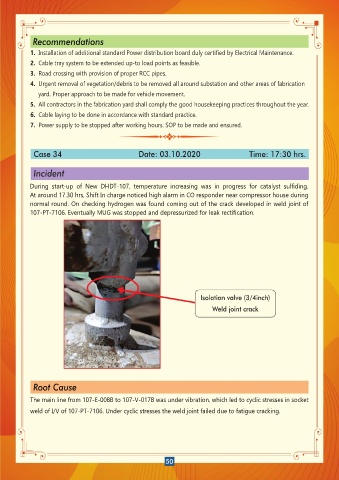

During start-up of New DHDT-107, temperature increasing was in progress for catalyst sulfiding.

At around 17.30 hrs, Shift In charge noticed high alarm in CO responder near compressor house during

normal round. On checking hydrogen was found coming out of the crack developed in weld joint of

107-PT-7106. Eventually MUG was stopped and depressurized for leak rectification.

Isolation valve (3/4inch)

Weld joint crack

Root Cause

The main line from 107-E-008B to 107-V-017B was under vibration, which led to cyclic stresses in socket

weld of I/V of 107-PT-7106. Under cyclic stresses the weld joint failed due to fatigue cracking.

50