Page 49 - Flip IOCL Book.cdr

P. 49

Recommendations

1. Replacement of 10X6"" Inlet spool piece of remaining two spool pieces PSVs (77-PSV-3658/3660) with

material specification of P11 or higher metallurgy i.e P5/P9.Material availability to be ensured by MM.

Replacement can be done without unit shutdown.

2. Due to recurring weld failure, Stress analysis to be carried out for any support / vibration related issues.

Case 30 Date: 02.07.2020 Time: 19:55 hrs.

Incident

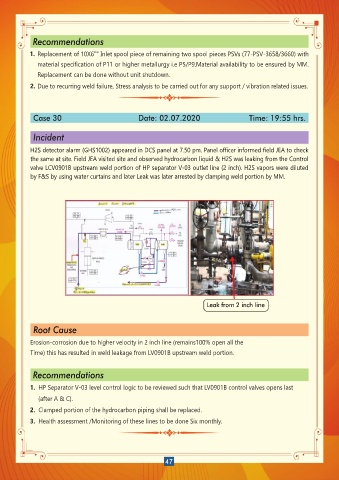

H2S detector alarm (GHS1002) appeared in DCS panel at 7.50 pm. Panel officer informed field JEA to check

the same at site. Field JEA visited site and observed hydrocarbon liquid & H2S was leaking from the Control

valve LCV0901B upstream weld portion of HP separator V-03 outlet line (2 inch). H2S vapors were diluted

by F&S by using water curtains and later Leak was later arrested by clamping weld portion by MM.

Leak from 2 inch line

Root Cause

Erosion-corrosion due to higher velocity in 2 inch line (remains100% open all the

Time) this has resulted in weld leakage from LV0901B upstream weld portion.

Recommendations

1. HP Separator V-03 level control logic to be reviewed such that LV0901B control valves opens last

(after A & C).

2. Clamped portion of the hydrocarbon piping shall be replaced.

3. Health assessment /Monitoring of these lines to be done Six monthly.

47