Page 48 - RFQ 01-2020 MHRA Kimball Street Warrenstreet Qualifications Statement

P. 48

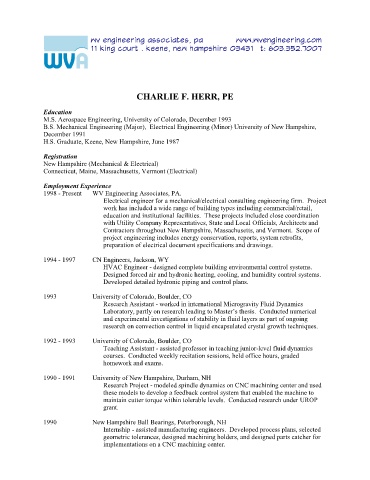

wv engineering associates, pa www.wvengineering.com

11 king court . keene, new hampshire 03431 t: 603.352.7007

CHARLIE F. HERR, PE

Education

M.S. Aerospace Engineering, University of Colorado, December 1993

B.S. Mechanical Engineering (Major), Electrical Engineering (Minor) University of New Hampshire,

December 1991

H.S. Graduate, Keene, New Hampshire, June 1987

Registration

New Hampshire (Mechanical & Electrical)

Connecticut, Maine, Massachusetts, Vermont (Electrical)

Employment Experience

1998 - Present WV Engineering Associates, PA.

Electrical engineer for a mechanical/electrical consulting engineering firm. Project

work has included a wide range of building types including commercial/retail,

education and institutional facilities. These projects included close coordination

with Utility Company Representatives, State and Local Officials, Architects and

Contractors throughout New Hampshire, Massachusetts, and Vermont. Scope of

project engineering includes energy conservation, reports, system retrofits,

preparation of electrical document specifications and drawings.

1994 - 1997 CN Engineers, Jackson, WY

HVAC Engineer - designed complete building environmental control systems.

Designed forced air and hydronic heating, cooling, and humidity control systems.

Developed detailed hydronic piping and control plans.

1993 University of Colorado, Boulder, CO

Research Assistant - worked in international Microgravity Fluid Dynamics

Laboratory, partly on research leading to Master’s thesis. Conducted numerical

and experimental investigations of stability in fluid layers as part of ongoing

research on convection control in liquid encapsulated crystal growth techniques.

1992 - 1993 University of Colorado, Boulder, CO

Teaching Assistant - assisted professor in teaching junior-level fluid dynamics

courses. Conducted weekly recitation sessions, held office hours, graded

homework and exams.

1990 - 1991 University of New Hampshire, Durham, NH

Research Project - modeled spindle dynamics on CNC machining center and used

these models to develop a feedback control system that enabled the machine to

maintain cutter torque within tolerable levels. Conducted research under UROP

grant.

1990 New Hampshire Ball Bearings, Peterborough, NH

Internship - assisted manufacturing engineers. Developed process plans, selected

geometric tolerances, designed machining holders, and designed parts catcher for

implementations on a CNC machining center.