Page 186 - Buy Premium Tools ATORN Catalogue

P. 186

Tools for threads

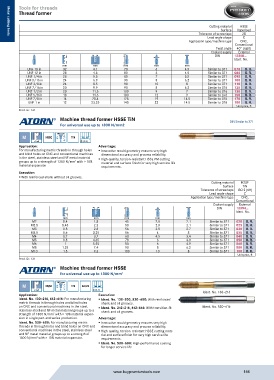

Thread former

Cutting material HSSE

Surface Vaporised

Tolerance of screw taps 2B

Lead angle shape C

Metal cutting tools

Metal cutting tools

Application type/machine type CNC,

Conventional

Twist angle 40° (right)

Coolant supply External

DIN 13358...

Ident. No.

mm mm mm mm mm

UNF 10 in 32 4.1 70 6 4.9 Similar to 371 070 O. R.

UNF 12 in 28 4.6 80 6 4.9 Similar to 371 080 O. R.

UNF 1/4 in 28 5.5 80 7 5.5 Similar to 371 090 O. R.

UNF 5/16 in 24 6.9 90 8 6.2 Similar to 371 100 O. R.

UNF 3/8 in 24 8.5 90 10 8 Similar to 371 110 O. R.

UNF 7/16 in 20 9.9 90 8 6.2 Similar to 376 120 O. R.

UNF 1/2 in 20 11.5 100 9 7 Similar to 376 130 O. R.

UNF 5/8 in 18 14.5 100 12 9 Similar to 376 150 O. R.

UNF 7/8 in 14 20.4 125 19 14.5 Similar to 376 170 O. R.

UNF 1 in 12 23.25 140 22 14.5 Similar to 376 180 O. R.

Unit price, €

Prod. Gr. 131

Machine thread former HSSE TiN

For universal use up to 1300 N/mm2 DIN Similar to 371

CNC/conv.

M HSSE TiN

1xd C (2-3)

Application: Advantage:

For manufacturing metric threads in through holes Innovative mould geometry ensures very high

and blind holes on CNC and conventional machines dimensional accuracy and process reliability.

in the steel, stainless steel and NF metal material High-quality, torsion-resistant HSSE PM cutting

groups up to a strength of 1300 N/mm with > 10% material and surface finish for very high service life

2

material expansion requirements.

Execution:

With reinforced shank without oil grooves.

Cutting material HSSE

Surface TiN

Tolerance of screw taps ISO 2 (6H)

Lead angle shape C

Application type/machine type CNC,

Conventional

Coolant supply External

DIN 13394...

Ident. No.

mm mm mm mm mm

M2 0.4 1.8 45 2.8 2.1 Similar to 371 020 O. R.

M2.5 0.45 2.3 50 2.8 2.1 Similar to 371 025 O. R.

M3 0.5 2.8 56 3.5 2.7 Similar to 371 030 O. R.

M3.5 0.6 3.25 56 4 3 Similar to 371 035 O. R.

M4 0.7 3.7 63 4.5 3.4 Similar to 371 040 O. R.

M5 0.8 4.65 70 6 4.9 Similar to 371 050 O. R.

M6 1 5.55 80 6 4.9 Similar to 371 060 O. R.

M8 1.25 7.4 90 8 6.2 Similar to 371 080 O. R.

M10 1.5 9.3 100 10 8 Similar to 371 100 O. R.

Unit price, €

Prod. Gr. 131

Machine thread former HSSE

for universal use up to 1300 N/mm 2

CNC/conv.

M HSSE TiN AlCrN

3xd C (2-3) Ident. No. 130–216

Application: Execution:

Ident. No. 130–216, 612–616: For manufacturing Ident. No. 130–200, 530–600: With reinforced

metric threads in through holes and blind holes shank and oil grooves.

on CNC and conventional machines in the steel, Ident. No. 212–216, 612–616: With transition-fit Ident. No. 530–616

stainless steel and NF metal material groups up to a shank and oil grooves.

strength of 1300 N/mm with > 10% material expan-

2

sion in single part and series production. Advantage:

Ident. No. 530–600: For manufacturing metric Innovative mould geometry ensures very high

threads in through holes and blind holes on CNC and dimensional accuracy and process reliability.

conventional machines in the steel, stainless steel High-quality, torsion-resistant HSSE cutting mate-

and NF metal material groups up to a strength of rial and surface finish for very high service life

1300 N/mm with > 10% material expansion. requirements.

2

Ident. No. 530–600: High-performance coating

for longer service life

www.buypremiumtools.com 186