Page 191 - Buy Premium Tools ATORN Catalogue

P. 191

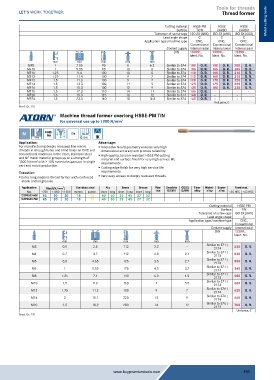

Tools for threads

Thread former

Cutting material HSSE-PM HSSE HSSE Metal cutting tools

Surface TiCN CARBO CARBO

Tolerance of screw taps ISO 2X (6HX) ISO 2X (6HX) ISO 3X (6GX)

Lead angle shape C C C

Application type/machine type CNC, CNC, CNC,

Conventional Conventional Conventional

Coolant supply Internal radial Internal axial Internal axial

DIN 13399... 13399... 13399...

Ident. No. Ident. No. Ident. No.

mm mm mm mm mm

MF8 1 7.55 90 8 6.2 Similar to 374 100 O. R. 150 O. R. 200 O. R.

MF10 1 9.55 90 10 8 Similar to 374 105 O. R. 155 O. R. 205 O. R.

MF10 1.25 9.4 100 10 8 Similar to 374 110 O. R. 160 O. R. 210 O. R.

MF12 1.25 11.4 100 9 7 Similar to 374 115 O. R. 165 O. R. 215 O. R.

MF12 1.5 11.3 100 9 7 Similar to 374 120 O. R. 170 O. R. 220 O. R.

MF14 1.5 13.3 100 11 9 Similar to 374 125 O. R. 175 O. R. 225 O. R.

MF16 1.5 15.3 100 12 9 Similar to 374 130 O. R. 180 O. R. 230 O. R.

MF18 1.5 17.3 110 14 11 Similar to 374 135 O. R. - - - -

MF20 1.5 19.3 125 16 12 Similar to 374 140 O. R. - - - -

MF24 1.5 23.3 140 18 14.5 Similar to 374 145 O. R. - - - -

Unit price, €

Prod. Gr. 131

Machine thread former overlong HSSE-PM TiN

for universal use up to 1300 N/mm 2

CNC/conv.

M HSSE- TiN

PM

3xd C (2-3) IK

Application: Advantage:

For manufacturing deeply recessed fine metric Innovative mould geometry ensures very high

threads in through holes and blind holes on CNC and dimensional accuracy and process reliability.

conventional machines in the steel, stainless steel High-quality, torsion-resistant HSSE PM cutting

and NF metal material groups up to a strength of material and surface finish for very high service life

1300 N/mm with > 10% material expansion in single requirements.

2

part and series production.

Cutting edge finish for very high service life

Execution: requirements.

Extra-long machine thread former with reinforced Very easy access to deeply recessed threads.

shank and oil grooves

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13399530-600 45 30 20 18 12 40 50 35 45 27 32

13399620-700 45 30 20 18 12 40 50 35 45 27 32

Cutting material HSSE-PM

Surface TiN

Tolerance of screw taps ISO 2X (6HX)

Lead angle shape C

Application type/machine type CNC,

Conventional

Coolant supply Internal axial

DIN 13399...

Ident. No.

mm mm mm mm mm

M3 0.5 2.8 112 2.2 - Similar to 371 | 530 O. R.

2174

M4 0.7 3.7 112 2.8 2.1 Similar to 371 | 540 O. R.

2174

M5 0.8 4.65 125 3.5 2.7 Similar to 371 | 550 O. R.

2174

M6 1 5.55 125 4.5 3.7 Similar to 371 | 560 O. R.

2174

M8 1.25 7.4 140 6.0 4.9 Similar to 371 | 580 O. R.

2174

M10 1.5 9.3 160 7 5.5 Similar to 371 | 600 O. R.

2174

M12 1.75 11.2 180 9 7 Similar to 376 | 620 O. R.

2174

M16 2 15.1 220 12 9 Similar to 376 | 660 O. R.

2174

M20 2.5 18.9 280 16 12 Similar to 376 | 700 O. R.

2174

Unit price, €

Prod. Gr. 131

www.buypremiumtools.com 191