Page 193 - Buy Premium Tools ATORN Catalogue

P. 193

Tools for threads

Thread milling cutter

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat. Metal cutting tools

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13498080-202 110 100 80 90 70 210 230 190 190 170 170 210 140 80 40 30 30

13498180-302 120 110 90 100 80 220 240 200 200 180 180 220 150 90 50 40 40

Surface Uncoated TiAlN

d1 (mm) Pitch (mm) Suitable l1 (mm) l2 (mm) l3 (mm) Shaft Ø Number fz steel 13498... 13498...

from thread (mm) of cutting 1000 Ident. No. Ident. No.

size edges (PCS) (mm)

8 0.5 M10 64 16 16 8 4 0.05 080 (O. R.) 180 O. R.

8 0.75 M10 64 16 16 8 4 0.05 085 (O. R.) 185 O. R.

10 1 M12 70 16 25 10 4 0.05 100 (O. R.) 201 O. R.

10 1.5 M14 70 16 25 10 4 0.05 105 (O. R.) 205 O. R.

12 1 M16 80 20 31 12 4 0.06 120 (O. R.) 220 O. R.

12 1.5 M16 80 20 31 12 4 0.06 125 (O. R.) 225 O. R.

16 1 M20 90 25 40 16 5 0.06 160 (O. R.) 260 (O. R.)

16 1.5 M22 90 25 40 16 5 0.07 165 (O. R.) 265 (O. R.)

16 2 M22 90 25 40 16 5 0.07 167 (O. R.) 267 (O. R.)

20 1.5 M26 105 33 50 20 5 0.09 200 (O. R.) 300 O. R.

20 2 M27 105 33 50 20 5 0.09 202 (O. R.) 302 (O. R.)

Unit price, €

Prod. Gr. 132

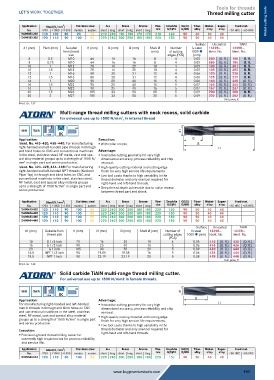

Multi-range thread milling cutters with neck recess, solid carbide

for universal use up to 1500 N/mm , in internal thread

2

HA

VHM TiAlN d1

2xd IK

Application: Execution: l2

Ident. No. 410–420, 430–440: For manufacturing With collar recess. l3

right-handed and left-handed pipe threads in through l1

and blind holes on CNC and conventional machines Advantage:

in the steel, stainless steel, NF metal, cast and spe- Innovative cutting geometry for very high

cial alloy material groups up to a strength of 1500 N/ dimensional accuracy, process reliability and chip

mm in single part and series production. removal.

2

Ident. No. 424–428, 444–448: For manufacturing High-quality cutting material and cutting edge

right-handed and left-handed NPT threads (National finish for very high service life requirements.

Piper Tap) in through and blind holes on CNC and Low tool costs thanks to high variability in the

conventional machines in the steel, stainless steel, thread diameter and only one tool required for

NF metal, cast and special alloy material groups right-hand and left-hand threads.

up to a strength of 1500 N/mm in single part and Deep thread depth achievable due to collar recess

2

series production. between thread part and shank.

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13498410-420 120 110 90 100 80 220 240 200 200 180 180 220 150 90 50 40 40

13498424-428 120 110 90 100 80 220 240 200 200 180 180 220 150 90 50 40 40

13498430-440 120 110 90 100 80 220 240 200 200 180 180 220 150 90 50 40 40

13498444-448 120 110 90 100 80 220 240 200 200 180 180 220 150 90 50 40 40

Surface Uncoated TiAlN

d1 (mm) Suitable from l1 (mm) l2 (mm) l3 (mm) Shaft Ø (mm) Number of fz steel 13498... 13498...

thread size cutting edges 1000 (mm) Ident. No. Ident. No.

(PCS)

10 G 1/4 inch 70 16 25 10 4 0.05 410 (O. R.) 430 (O. R.)

16 G 1/2 inch 90 25 40 16 5 0.06 416 (O. R.) 436 (O. R.)

20 G 1 inch 105 33 50 20 5 0.09 420 (O. R.) 440 (O. R.)

14.5 NPT 1/2 inch 90 19.05 19.05 16 5 0.06 424 (O. R.) 444 (O. R.)

18.5 NPT 1 inch 90 23.19 23.19 20 5 0.08 428 (O. R.) 448 (O. R.)

Unit price, €

Prod. Gr. 132

Solid carbide TiAlN multi-range thread milling cutter.

For universal use up to 1500 N/mm2 in female threads.

HA

VHM TiAlN d1

2xd IK

Application: Advantage: l2

For manufacturing right-handed and left-handed Innovative cutting geometry for very high l1

metric threads in through and blind holes on CNC dimensional accuracy, process reliability and chip

and conventional machines in the steel, stainless removal.

steel, NF metal, cast and special alloy material High-quality cutting material and cutting edge

groups up to a strength of 1500 N/mm in single part finish for very high service life requirements.

2

and series production.

Low tool costs thanks to high variability in the

Execution: thread diameter and only one tool required for

Precision-ground thread milling cutter for right-hand and left-hand threads.

extremely high requirements for process reliability

and service life.

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13496560-612 120 110 90 100 80 220 240 200 200 180 180 220 150 90 50 40 40

www.buypremiumtools.com 193