Page 199 - Buy Premium Tools ATORN Catalogue

P. 199

Tools for threads

Thread cutting sets

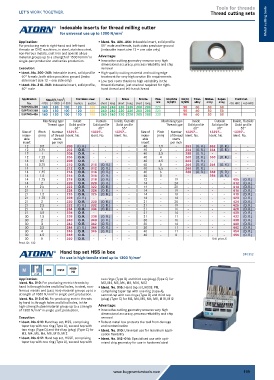

Indexable inserts for thread milling cutter Metal cutting tools

for universal use up to 1300 N/mm 2

Application: Ident. No. 406–456: Indexable insert, solid profile

For producing metric right-hand and left-hand 55° male and female, both sides precision-ground

threads on CNC machines, in steel, stainless steel, (indexable insert size 12 = one side only)

non-ferrous metals, cast iron and special alloys

material groups up to a strength of 1500 N/mm in Advantage:

2

single-part production and series production. Innovative cutting geometry ensures very high

dimensional accuracy, process reliability and chip

Execution: removal

Ident. No. 200–268: Indexable insert, solid profile High-quality cutting material and cutting edge

60° female, both sides precision-ground (index- treatment for very high service life requirements

able insert size 12 = one side only) Low tool costs thanks to high variability in the

Ident. No. 310–368: Indexable insert, solid profile, thread diameter, just one tool required for right-

60° male hand thread and left-hand thread

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13397200-268 140 130 100 120 100 240 240 220 220 200 200 220 90 60 50 50

13397310-368 140 130 100 120 100 240 240 220 220 200 200 220 90 60 50 50

13397406-456 140 130 100 120 100 240 240 220 220 200 200 220 90 60 50 50

Machining type Inside Outside Inside, Outside Machining type Inside Outside Inside, Outside

Thread type Solid profile Solid profile Solid profile Thread type Solid profile Solid profile Solid profile

60° 60° 55° 60° 60° 55°

Size of Pitch Number 13397... 13397... 13397... Size of Pitch Number 13397... 13397... 13397...

index- (mm) of thread Ident. No. Ident. No. Ident. No. index- (mm) of thread Ident. No. Ident. No. Ident. No.

able starts able starts

insert per inch insert per inch

12 0.5 - 200 (O. R.) - - - - 40 1.5 - 252 (O. R.) 352 (O. R.) - -

12 0.75 - 202 O. R. - - - - 40 2 - 254 (O. R.) 354 (O. R.) - -

12 1 - 204 O. R. - - - - 40 3.5 - 258 (O. R.) - - - -

12 1.25 - 206 O. R. - - - - 40 4 - 260 (O. R.) 360 (O. R.) - -

14 0.5 - 208 O. R. - - - - 40 4.5 - 262 (O. R.) - - - -

14 0.75 - 210 O. R. 310 (O. R.) - - 40 5 - 264 (O. R.) 364 (O. R.) - -

14 1 - 212 O. R. 312 (O. R.) - - 40 5.5 - 266 (O. R.) - - - -

14 1.25 - 214 O. R. 314 (O. R.) - - 40 6 - 268 (O. R.) 368 (O. R.) - -

14 1.5 - 216 O. R. 316 (O. R.) - - 40 3 - - - 356 (O. R.) - -

14 1.75 - 218 O. R. 318 (O. R.) - - 12 - 19 - - - - 406 (O. R.)

14 2 - 220 O. R. 320 (O. R.) - - 14 - 24 - - - - 412 (O. R.)

14 2.5 - 222 O. R. 322 (O. R.) - - 14 - 20 - - - - 414 (O. R.)

21 1 - 224 O. R. 324 (O. R.) - - 14 - 19 - - - - 416 (O. R.)

21 1.5 - 226 O. R. 326 (O. R.) - - 14 - 16 - - - - 418 (O. R.)

21 1.75 - 228 (O. R.) - - - - 14 - 14 - - - - 420 (O. R.)

21 2 - 230 O. R. 330 (O. R.) - - 21 - 20 - - - - 424 (O. R.)

21 2.5 - 232 (O. R.) 332 (O. R.) - - 21 - 19 - - - - 426 (O. R.)

21 3 - 234 O. R. 334 (O. R.) - - 21 - 16 - - - - 428 (O. R.)

21 3.5 - 236 O. R. - - - - 21 - 14 - - - - 430 (O. R.)

30 1.5 - 238 O. R. 338 (O. R.) - - 21 - 11 - - - - 432 (O. R.)

30 2 - 240 O. R. 340 (O. R.) - - 30 - 16 - - - - 438 (O. R.)

30 3 - 242 O. R. 342 (O. R.) - - 30 - 14 - - - - 440 (O. R.)

30 3.5 - 244 (O. R.) 344 (O. R.) - - 30 - 11 - - - - 442 (O. R.)

30 4 - 246 O. R. 346 (O. R.) - - 40 - 11 - - - - 454 (O. R.)

30 4.5 - 248 O. R. - - - - 40 - 8 - - - - 456 (O. R.)

30 5 - 250 O. R. - - - - Unit price, €

Prod. Gr. 132

Hand tap set HSS in box DIN 352

for use in high-tensile steel up to 1300 N/mm 2

M HSS HSSE HSSE-

PM

1xd

Application: two rings (Type D) and third tap (plug) (Type C) for

Ident. No. 010: For producing metric threads by M3, M4, M5, M6, M8, M10, M12

hand in through holes and blind holes, in steel, non- Ident. No. 016: Hand tap set, HSSE-PM,

ferrous metals and (cast iron) material groups up to a comprising taper tap with one ring (Type A),

strength of 1000 N/mm in single-part production. second tap with two rings (Type D) and third tap

2

Ident. No. 012–016: For producing metric threads (plug) (Type C) for M3, M4, M5, M6, M8, M10, M12

by hand in through holes and blind holes, in the

high-strength steel material group up to a strength Advantage:

of 1300 N/mm in single-part production. Innovative cutting geometry ensures very high

2

dimensional accuracy, process reliability and chip

Execution: removal

Ident. No. 010: Hand tap set, HSS, comprising Robust metal box protects the tool from damage

taper tap with one ring (Type A), second tap with and contamination

two rings (Type D) and third tap (plug) (Type C) for Ident. No. 010: Universal use for maximum appli-

M3, M4, M5, M6, M8, M10, M12 cation flexibility

Ident. No. 012: Hand tap set, HSSE, comprising Ident. No. 012–016: Specialised use with opti-

taper tap with one ring (Type A), second tap with mised chip geometry for use in hardened steel

www.buypremiumtools.com 199