Page 203 - Buy Premium Tools ATORN Catalogue

P. 203

Tools for threads

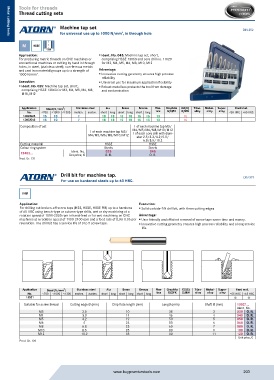

Thread cutting sets

Machine tap set DIN 352

for universal use up to 1000 N/mm , in through hole

2

Metal cutting tools

Metal cutting tools

M HSSE

3xd

Application: Ident. No. 045: Machine tap set, short,

For producing metric threads on CNC machines or comprising HSSE 13063 and core drill no. 11020

conventional machines or cutting by hand in through for M3, M4, M5, M6, M8, M10, M12

holes, in steel, (stainless steel), non-ferrous metals

and cast iron material groups up to a strength of Advantage:

1000 N/mm . 2 Innovative cutting geometry ensures high process

reliability

Execution: Universal use for maximum application flexibility

Ident. No. 025: Machine tap set, short, Robust metal box protects the tool from damage

comprising HSSE 13063 for M3, M4, M5, M6, M8, and contamination

M10, M12

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13403025 15 10 9 18 18 15 18 15 15 13 16

13403045 15 10 9 18 18 15 18 15 15 13 16

Composition of set 1 of each machine tap M3/

1 of each machine tap M3/ M4/M5/M6/M8/M10/M12

1 of each core drill with diam-

M4/M5/M6/M8/M10/M12 eter 2.5/3.3/4.2/5.0/

6.8/8.5/10.2

Cutting material HSSE HSSE

Colour ring system Steels Steels

045

025

Ident. No.

13403... Set price, € O. R. O. R.

Prod. Gr. 131

Drill bit for machine tap. DIN 374

For use on hardened steels up to 63 HRC.

VHM

Application: Execution:

For drilling out broken-off screw taps (HSS, HSSE, HSSE PM) up to a hardness Solid carbide-TiN drill bit, with three cutting edges

of 65 HRC using bench-type or column-type drills, wet or dry machining at a

rotation speed of 1000-2000 rpm in hand-feed or for wet machining on CNC Advantage:

machines at a rotation speed of 1400-2400 rpm and a feed rate of 0.03-0.06 per User-friendly and efficient removal of screw taps saves time and money.

revolution. The drill bit has a service life of 3 to 5 screw taps. Innovative cutting geometry ensures high process reliability and a long service

life.

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13521

Suitable for screw thread Cutting edge Ø (mm) Chip flute length (mm) Length (mm) Shaft Ø (mm) 13521...

Ident. No.

M3 2.5 10 38 3 030 O. R.

M4 3.3 14 46 4 040 O. R.

M5 4.2 19 50 5 050 O. R.

M6 5 23 50 6 060 O. R.

M8 6.8 23 60 7 080 O. R.

M10 8.5 25 80 9 100 O. R.

M12 10.2 35 80 11 120 O. R.

Unit price, €

Prod. Gr. 139

www.buypremiumtools.com 203