Page 249 - Buy Premium Tools ATORN Catalogue

P. 249

Milling tools

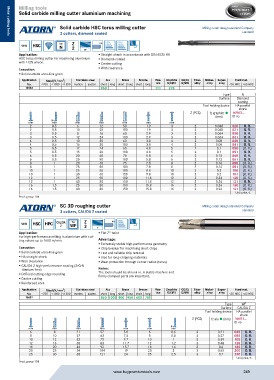

Solid carbide milling cutter aluminium machining

Solid carbide HSC torus milling cutter Milling cutter design standard Company

2 cutters, diamond-coated standard

Metal cutting tools

Metal cutting tools

Z

VHM HSC Typ 2 HA

N

Application: Straight shank in accordance with DIN 6535 HA

HSC torus milling cutter for machining aluminium Diamond-coated

with >12% silicon. Centre cutting

Execution: With clearance

Solid carbide ultra-fine grain

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16963 950 300 275

Type N

Surface Diamond

coating

Tool holding device HA parallel

shank

Z (PCS) fz graphite 16963...

(mm) ID no.

mm mm mm mm mm mm mm

2 0.5 6 12 50 1.9 3 2 0.048 020 O. R.

2 0.5 10 20 100 1.9 3 2 0.048 021 O. R.

3 0.5 8 16 60 2.9 3 2 0.064 030 O. R.

3 0.5 12 24 100 2.9 3 2 0.064 031 O. R.

4 0.5 10 20 60 3.8 4 2 0.08 040 O. R.

4 0.5 15 30 100 3.8 4 2 0.08 041 O. R.

5 0.5 12 24 60 4.8 5 2 0.1 050 (O. R.)

5 0.5 15 30 100 4.8 5 2 0.1 051 O. R.

6 0.5 20 40 75 5.8 6 2 0.12 060 O. R.

6 0.5 25 50 100 5.8 6 2 0.12 061 O. R.

8 1 20 40 75 7.8 8 2 0.16 080 (O. R.)

8 1 25 50 100 7.8 8 2 0.16 081 (O. R.)

10 1 25 50 100 9.8 10 2 0.2 100 (O. R.)

10 1 30 60 150 9.8 10 2 0.2 101 (O. R.)

12 1 25 50 100 11.8 12 2 0.24 120 (O. R.)

12 1 40 80 150 11.8 12 2 0.24 121 O. R.

16 1.5 25 50 100 15.8 16 2 0.26 160 (O. R.)

16 1.5 40 80 150 15.8 16 2 0.26 161 (O. R.)

Unit price, €

Prod. group 108

SC 3D roughing cutter Milling cutter design standard Company

3 cutters, CALIDA Z coated standard

Typ

VHM HSC HPC CALIDA WF Z HA

3

Z

Application: 7° Flat 7° twist

For high-performance milling in aluminium with cut-

ting values up to 1600 m/min. Advantage:

Extremely stable high-performance geometry

Execution: Chip breaker for machining short chips

Solid carbide ultra-fine grain Fast and reliable chip removal

HA straight shank Also for long-chipping materials

With clearance Wear protection through corner radius (torus)

CALIDA Z high-performance coating (ZrCrN

titanium-free) Notes:

Defined cutting edge rounding The tools should be shrunk-in. A stable machine and

firmly clamped parts are important.

Centre cutting

Reinforced core

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16651 850 1000 800 950 600 700

Type WF

Surface CALIDA Z

Tool holding device HA parallel

shank

Z (PCS) fz alu (mm) 16651...

ID no.

mm mm mm mm mm mm mm

6 8 21 57 5.8 6 0.6 3 0.21 060 O. R.

8 10 27 63 7.8 8 0.8 3 0.27 080 O. R.

10 12 32 72 9.7 10 1 3 0.39 100 O. R.

12 16 38 83 11.7 12 1.2 3 0.48 120 O. R.

16 20 44 92 15.7 16 1.6 3 0.6 160 O. R.

20 25 54 104 19 20 2 3 0.65 200 O. R.

25 30 65 121 24 25 2.5 3 0.7 250 O. R.

Unit price, €

Prod. group 108

www.buypremiumtools.com 249