Page 609 - Introduction to Business

P. 609

CHAPTER 16 Managing Business Operations 583

time, products that exhibit abnormal variations would not conform to specifica-

tions. When the production system is producing products with normal variations,

we say it is an in-control production system; when the production system is in-control production system The

producing products with abnormal variations, we say it is an out-of-control production system where products

produced exhibit normal variations

production system and we should perform any necessary adjustments to bring it

out-of-control production system The

in control.

production system where products

By means of the control chart, the operations manager can help the production produced exhibit abnormal variations

system operators to detect when product variations are normal and when they are control chart A chart used to detect if

abnormal. For example, one of the design specifications for a box of detergent is the production system is in control or

that it must contain 48 ounces. Using historical data and statistical analysis, the out of control

operations manager has determined that when the production system is in control

and a random sample of ten boxes is taken, the average number of ounces per box

is 48 (although individual boxes may contain more or fewer ounces per box). How-

ever, due to normal variations in the filling process, some samples could have an

average as high as 48.3 ounces, called the upper control limit, or as

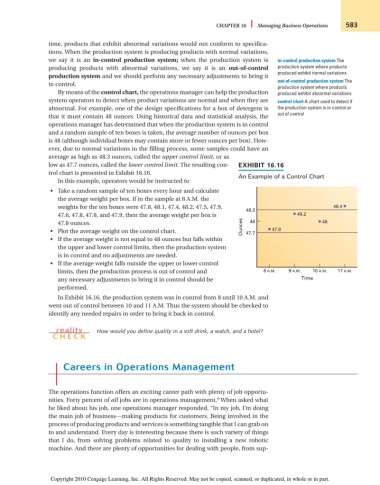

low as 47.7 ounces, called the lower control limit. The resulting con- EXHIBIT 16.16

trol chart is presented in Exhibit 16.16.

An Example of a Control Chart

In this example, operators would be instructed to

• Take a random sample of ten boxes every hour and calculate

the average weight per box. If in the sample at 8 A.M. the

weights for the ten boxes were 47.8, 48.1, 47.4, 48.2, 47.5, 47.9, 48.4

48.3

47.6, 47.8, 47.8, and 47.9, then the average weight per box is 48.2

47.8 ounces. Ounces 48 48

• Plot the average weight on the control chart. 47.7 47.8

• If the average weight is not equal to 48 ounces but falls within

the upper and lower control limits, then the production system

is in control and no adjustments are needed.

• If the average weight falls outside the upper or lower control

limits, then the production process is out of control and 8 A.M. 9 A.M. 10 A.M. 11 A.M.

any necessary adjustments to bring it in control should be Time

performed.

In Exhibit 16.16, the production system was in control from 8 until 10 A.M. and

went out of control between 10 and 11 A.M. Thus the system should be checked to

identify any needed repairs in order to bring it back in control.

reality How would you define quality in a soft drink, a watch, and a hotel?

CH ECK

Careers in Operations Management

The operations function offers an exciting career path with plenty of job opportu-

9

nities. Forty percent of all jobs are in operations management. When asked what

he liked about his job, one operations manager responded, “In my job, I’m doing

the main job of business—making products for customers. Being involved in the

process of producing products and services is something tangible that I can grab on

to and understand. Every day is interesting because there is such variety of things

that I do, from solving problems related to quality to installing a new robotic

machine. And there are plenty of opportunities for dealing with people, from sup-

Copyright 2010 Cengage Learning, Inc. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part.