Page 16 - Станочный парк английская версия

P. 16

METALWORKING EQUIPMENT AND TOOLS

Substantiation of the design of the block boring tool

The aim of the development is to increase the efficiency of boring of body

parts in the conditions of flexible production on the basis of multi-purpose CNC

machines

In such a production, the variety of

machined parts and the technology for

processing precise holes in these parts

require a large number of boring mandrels,

both on machines and in the warehouse. For

example, a set of mandrels for machining

parts such as "feed box" of a 16K20 lathe

includes 34 mandrels.

Therefore, it is advisable to use a

block boring tool (BBT), which consists of

interchangeable functional blocks, which, in

various permutations, allows you to create

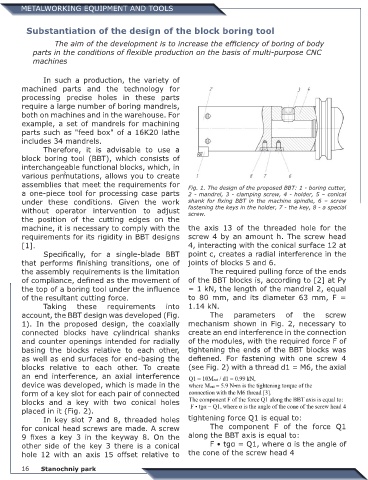

assemblies that meet the requirements for Fig. 1. The design of the proposed BBT: 1 - boring cutter,

a one-piece tool for processing case parts 2 - mandrel, 3 - clamping screw, 4 - holder, 5 – conical

under these conditions. Given the work shank for fixing BBT in the machine spindle, 6 – screw

without operator intervention to adjust fastening the keys in the holder, 7 - the key, 8 - a special

screw.

the position of the cutting edges on the

machine, it is necessary to comply with the the axis 13 of the threaded hole for the

requirements for its rigidity in BBT designs screw 4 by an amount h. The screw head

[1]. 4, interacting with the conical surface 12 at

Specifically, for a single-blade BBT point c, creates a radial interference in the

that performs finishing transitions, one of joints of blocks 5 and 6.

the assembly requirements is the limitation The required pulling force of the ends

of compliance, defined as the movement of of the BBT blocks is, according to [2] at Py

the top of a boring tool under the influence = 1 kN, the length of the mandrel 2, equal

of the resultant cutting force. to 80 mm, and its diameter 63 mm, F =

Taking these requirements into 1.14 kN.

account, the BBT design was developed (Fig. The parameters of the screw

1). In the proposed design, the coaxially mechanism shown in Fig. 2, necessary to

connected blocks have cylindrical shanks create an end interference in the connection

and counter openings intended for radially of the modules, with the required force F of

basing the blocks relative to each other, tightening the ends of the BBT blocks was

as well as end surfaces for end-basing the defiened. For fastening with one screw 4

blocks relative to each other. To create (see Fig. 2) with a thread d1 = M6, the axial

an end interference, an axial interference

device was developed, which is made in the

form of a key slot for each pair of connected

blocks and a key with two conical holes

placed in it (Fig. 2).

In key slot 7 and 8, threaded holes tightening force Q1 is equal to:

for conical head screws are made. A screw The component F of the force Q1

9 fixes a key 3 in the keyway 8. On the along the BBT axis is equal to:

other side of the key 3 there is a conical F • tgα = Q1, where α is the angle of

hole 12 with an axis 15 offset relative to the cone of the screw head 4

Stanochniy park