Page 217 - FreesStyler® Installation and Startup

P. 217

®

INSTALLATION AND STARTUP

Startup Procedure

Check Remaining Outputs

1) From the HMI, turn on EXIT ON and EXIT BOTH. Verify that both arms move in and water

comes on and then turn them off

2) Turn on TOP ON and TOP DOWN. Verify that the water spray nozzles are flowing and the

Top Wheel comes down. If it does not, confirm that there is grease on the gears and that the

rotation direction is correct. Turn off TOP DOWN so that the Top Wheel rises. If it “bangs”

while going up, close the Top Wheel air flow control located on the corresponding cylinder

and try again. If the Top Wheel does not go all the way up, slightly open the flow controls (the

flow controls alter the Top Wheel retract speed).

3) Turn on the ENTER ON and ENTER BOTH. Verify that the water spray nozzles are flowing in

the desired path. Confirm that the Entrance Wheels come in.

a) Turn on ENTER D/S and ENTER P/S and verify the 2” stroke of the corresponding cylinder.

DO NOT CHANGE THE FLOW CONTROLS ON THE ENTRANCE OR EXIT WHEELS YET. This will be done after the

final settings of air pressure penetration and bearing slope.

b) From the Output Board, force on the following lights one at a time and verify operation:

Outside Sign

• STOP ENTER

• SLOW ENTER

In-Bay Sign

• FWD EXIT

• STOP EXIT

• BWD EXIT

c) Force on RNS/WAX WTR and DA CHEM. Verify water and chemical flow

d) Force on the SPOT FREE and test (if applicable)

e) Force on TIRE HIGH and verify proper operation (if applicable)

f) Force on TIRE APP if CTA was purchased

g) Force on UNDERCARRIAGE and verify proper operation (if applicable)

h) Force on ENTER DOOR and EXIT DOOR. Verify proper operation (if applicable)

i) Force on DRYER and check rotation according to the Dryer manual (if applicable)

4) Close both side pods and manifold covers

5) Hit the Fault Reset and the FressStyler® should HOME at the exit end of the bay

6) Verify that no Faults have occurred at the Fault screen of the HMI

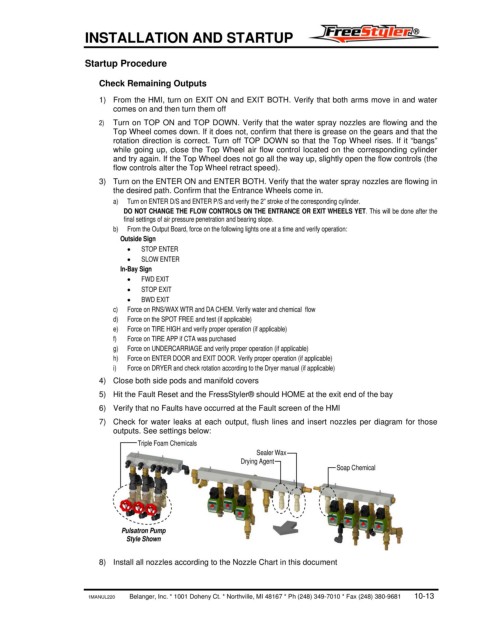

7) Check for water leaks at each output, flush lines and insert nozzles per diagram for those

outputs. See settings below:

Triple Foam Chemicals

Sealer Wax

Drying Agent

Soap Chemical

Pulsatron Pump

Style Shown

8) Install all nozzles according to the Nozzle Chart in this document

1MANUL220 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 10-13