Page 36 - DuraBlaster® Wheel Cleaner

P. 36

®

DURABLASTER WHEEL CLEANER

Maintenance

Disassembly Procedure

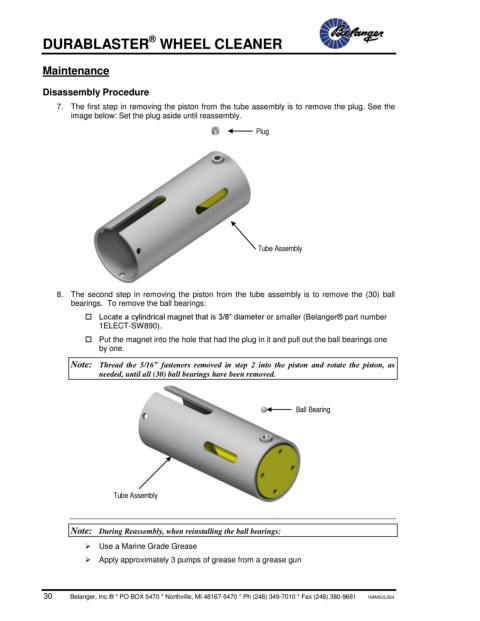

7. The first step in removing the piston from the tube assembly is to remove the plug. See the

image below: Set the plug aside until reassembly.

Plug

Tube Assembly

8. The second step in removing the piston from the tube assembly is to remove the (30) ball

bearings. To remove the ball bearings:

Locate a cylindrical magnet that is 3/8” diameter or smaller (Belanger® part number

1ELECT-SW890).

Put the magnet into the hole that had the plug in it and pull out the ball bearings one

by one.

Note: Thread the 5/16” fasteners removed in step 2 into the piston and rotate the piston, as

needed, until all (30) ball bearings have been removed.

Ball Bearing

Tube Assembly

Note: During Reassembly, when reinstalling the ball bearings:

Use a Marine Grade Grease

Apply approximately 3 pumps of grease from a grease gun

30 Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL054