Page 593 - Foton Workshop Manual - Auman EST-M

P. 593

Engine section – Engine (Cummins ISF3.8) EG - 77

IN

f. Turn the crankshaft in 360 degrees by the turning tool.

DI

Following the same procedures and technical specifications

above, measure the clearance of the following rocker arms

(E= exhaust valve, I= intake valve) If the clearance exceeds EG

the technical specification, the clearance shall be reset.

2E, 3I, 4E and 4I

TR

AX

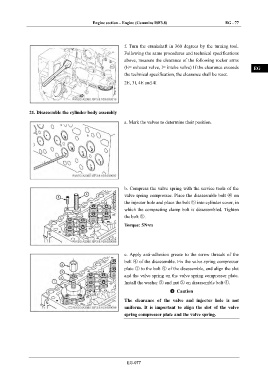

21. Disassemble the cylinder body assembly

FR

a. Mark the valves to determine their position.

ST

BR

BW

EL

b. Compress the valve spring with the service tools of the

valve spring compressor. Place the disassemble bolt ④ on

the injector hole and place the bolt ⑤ into cylinder cover, in

which the compacting clamp bolt is disassembled. Tighten

the bolt ⑤.

Torque: 5N•m

c. Apply anti-adhesion grease to the screw threads of the

bolt ④ of the disassemble. Fix the valve spring compressor

plate ① to the bolt ④ of the disassemble, and align the slot

and the valve spring on the valve spring compressor plate.

Install the washer ③ and nut ② on disassemble bolt ④.

Caution

The clearance of the valve and injector hole is not

uniform. It is important to align the slot of the valve

spring compressor plate and the valve spring.

EG-077