Page 591 - Foton Workshop Manual - Auman EST-M

P. 591

Engine section – Engine (Cummins ISF3.8) EG - 75

IN

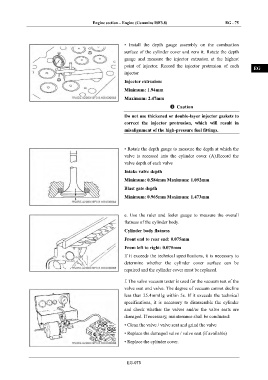

• Install the depth gauge assembly on the combustion

surface of the cylinder cover and zero it. Rotate the depth DI

gauge and measure the injector extrusion at the highest

point of injector. Record the injector protrusion of each

EG

injector

Injector extrusion:

TR

Minimum: 1.94mm

Maximum: 2.47mm

AX

Caution

Do not use thickened or double-layer injector gaskets to

FR

correct the injector protrusion, which will result in

misalignment of the high-pressure fuel fittings.

ST

• Rotate the depth gauge to measure the depth at which the

BR

valve is recessed into the cylinder cover (A).Record the

valve depth of each valve

BW

Intake valve depth

Minimum: 0.584mm Maximum: 1.092mm

EL

Blast gate depth

Minimum: 0.965mm Maximum: 1.473mm

e. Use the ruler and feeler gauge to measure the overall

flatness of the cylinder body.

Cylinder body flatness

Front end to rear end: 0.075mm

From left to right: 0.075mm

If it exceeds the technical specifications, it is necessary to

determine whether the cylinder cover surface can be

repaired and the cylinder cover must be replaced.

f. The valve vacuum tester is used for the vacuum test of the

valve seat and valve. The degree of vacuum cannot decline

less than 25.4mmHg within 5s. If it exceeds the technical

specifications, it is necessary to disassemble the cylinder

and check whether the valves and/or the valve seats are

damaged. If necessary, maintenance shall be conducted:

• Clean the valve / valve seat and grind the valve

• Replace the damaged valve / valve seat (if available)

• Replace the cylinder cover.

EG-075