Page 595 - Foton Workshop Manual - Auman EST-M

P. 595

Engine section – Engine (Cummins ISF3.8) EG - 79

IN

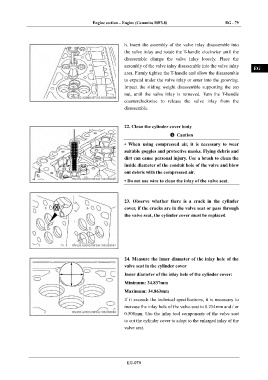

h. Insert the assembly of the valve inlay disassemble into

the valve inlay and rotate the T-handle clockwise until the DI

disassemble clamps the valve inlay loosely. Place the

assembly of the valve inlay disassemble into the valve inlay

EG

area. Firmly tighten the T-handle and allow the disassemble

to expand under the valve inlay or enter into the grooving.

TR

Impact the sliding weight disassemble supporting the top

nut, until the valve inlay is removed. Turn the T-handle

counterclockwise to release the valve inlay from the AX

disassemble.

FR

22. Clean the cylinder cover body

Caution ST

• When using compressed air, it is necessary to wear

suitable goggles and protective masks. Flying debris and BR

dirt can cause personal injury. Use a brush to clean the

inside diameter of the conduit hole of the valve and blow BW

out debris with the compressed air.

• Do not use wire to clean the inlay of the valve seat.

EL

23. Observe whether there is a crack in the cylinder

cover, if the cracks are in the valve seat or pass through

the valve seat, the cylinder cover must be replaced

24. Measure the inner diameter of the inlay hole of the

valve seat in the cylinder cover

Inner diameter of the inlay hole of the cylinder cover:

Minimum: 34.837mm

Maximum: 34.863mm

If it exceeds the technical specifications, it is necessary to

increase the inlay hole of the valve seat to 0.254mm and / or

0.508mm. Use the inlay tool components of the valve seat

to cut the cylinder cover to adapt to the enlarged inlay of the

valve seat.

EG-079