Page 625 - Foton Workshop Manual - Auman EST-M

P. 625

Engine section – Engine (Cummins ISF3.8) EG - 109

IN

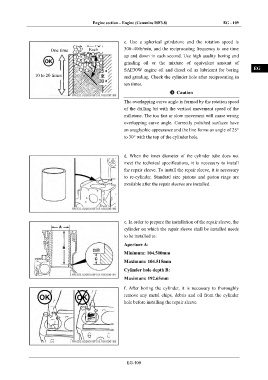

c. Use a spherical grindstone and the rotation speed is

One time Each 300~400r/min, and the reciprocating frequency is one time DI

up and down in each second. Use high quality boring and

grinding oil or the mixture of equivalent amount of

EG

SAE30W engine oil and diesel oil as lubricant for boring

10 to 20 times

and grinding. Check the cylinder hole after reciprocating in

ten times. TR

Caution

The overlapping curve angle is formed by the rotation speed AX

of the drilling bit with the vertical movement speed of the

millstone. The too fast or slow movement will cause wrong

FR

overlapping curve angle. Correctly polished surfaces have

an anaglyphic appearance and the line forms an angle of 25°

ST

to 30° with the top of the cylinder hole.

BR

d. When the inner diameter of the cylinder tube does not

meet the technical specifications, it is necessary to install

BW

the repair sleeve. To install the repair sleeve, it is necessary

to re-cylinder. Standard size pistons and piston rings are

available after the repair sleeves are installed. EL

e. In order to prepare the installation of the repair sleeve, the

cylinder on which the repair sleeve shall be installed needs

to be installed to:

Aperture A:

Minimum: 104.500mm

Maximum: 104.515mm

Cylinder hole depth B:

Maximum: 192.65mm

f. After boring the cylinder, it is necessary to thoroughly

remove any metal chips, debris and oil from the cylinder

hole before installing the repair sleeve.

EG-109