Page 622 - Foton Workshop Manual - Auman EST-M

P. 622

EG - 106 Engine section – Engine (Cummins ISF3.8)

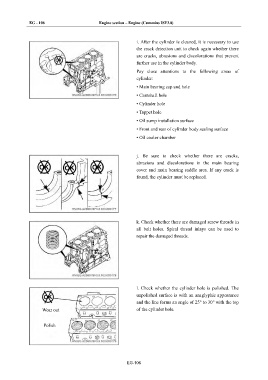

i. After the cylinder is cleaned, it is necessary to use

the crack detection unit to check again whether there

are cracks, abrasions and discolorations that prevent

further use in the cylinder body.

Pay close attentions to the following areas of

cylinder:

• Main bearing cap and hole

• Camshaft hole

• Cylinder hole

• Tappet hole

• Oil sump installation surface

• Front and rear of cylinder body sealing surface

• Oil cooler chamber

j. Be sure to check whether there are cracks,

abrasions and discolorations in the main bearing

cover and main bearing saddle area. If any crack is

found, the cylinder must be replaced.

k. Check whether there are damaged screw threads in

all bolt holes. Spiral thread inlays can be used to

repair the damaged threads.

l. Check whether the cylinder hole is polished. The

unpolished surface is with an anaglyphic appearance

and the line forms an angle of 25° to 30° with the top

Wear out of the cylinder hole.

Polish

EG-106