Page 879 - Workshop Manual - Aumark (BJ1051)

P. 879

31A-17

Transmission (646b/651b)-transmission assembly

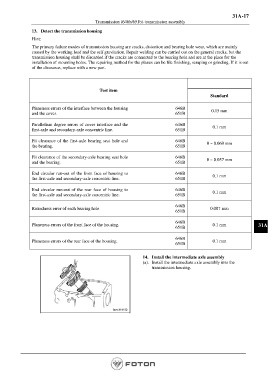

13. Detect the transmission housing

Hint:

The primary failure modes of transmission housing are cracks, distortion and bearing hole wear, which are mainly

caused by the working load and the self gravitation. Repair welding can be carried out on the general cracks, but the

transmission housing shall be discarded if the cracks are connected to the bearing hole and are at the place for the

installation of mounting holes. The repairing method for the planes can be file finishing, scraping or grinding. If it is out

of the clearance, replace with a new part.

Test item

Standard

Planeness errors of the interface between the housing 646B 0.15 mm

and the cover. 651B

Parallelism degree errors of cover interface and the 646B 0.1 mm

first-axle and secondary-axle concentric line. 651B

Fit clearance of the first-axle bearing seat hole and 646B 0 ~ 0.069 mm

the bearing. 651B

Fit clearance of the secondary-axle bearing seat hole 646B 0 ~ 0.057 mm

and the bearing. 651B

End circular run-out of the front face of housing to 646B 0.1 mm

the first-axle and secondary-axle concentric line. 651B

End circular run-out of the rear face of housing to 646B 0.1 mm

the first-axle and secondary-axle concentric line. 651B

646B

Roundness error of each bearing hole 0.007 mm

651B

646B

Planeness errors of the front face of the housing. 0.1 mm 31A

651B

646B

Planeness errors of the rear face of the housing. 0.1 mm

651B

14. Install the intermediate axle assembly

(a). Install the intermediate axle assembly into the

transmission housing.

Page 879