Page 18 - DuraBlaster® Wheel Cleaner

P. 18

®

DURABLASTER WHEEL CLEANER

Installation

DuraBlaster® Assembly and Placement

It is very important to understand the operation and activation of the DuraBlaster® to determine the

best location of the components.

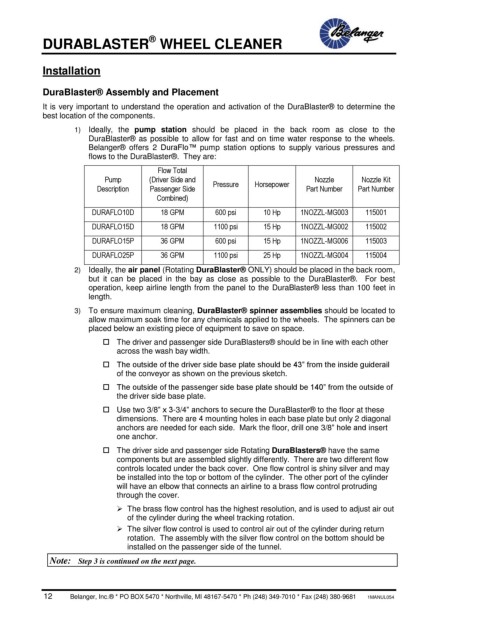

1) Ideally, the pump station should be placed in the back room as close to the

DuraBlaster® as possible to allow for fast and on time water response to the wheels.

Belanger® offers 2 DuraFlo™ pump station options to supply various pressures and

flows to the DuraBlaster®. They are:

Flow Total

Pump (Driver Side and Nozzle Nozzle Kit

Description Passenger Side Pressure Horsepower Part Number Part Number

Combined)

DURAFLO10D 18 GPM 600 psi 10 Hp 1NOZZL-MG003 115001

DURAFLO15D 18 GPM 1100 psi 15 Hp 1NOZZL-MG002 115002

DURAFLO15P 36 GPM 600 psi 15 Hp 1NOZZL-MG006 115003

DURAFLO25P 36 GPM 1100 psi 25 Hp 1NOZZL-MG004 115004

2) Ideally, the air panel (Rotating DuraBlaster® ONLY) should be placed in the back room,

but it can be placed in the bay as close as possible to the DuraBlaster®. For best

operation, keep airline length from the panel to the DuraBlaster® less than 100 feet in

length.

3) To ensure maximum cleaning, DuraBlaster® spinner assemblies should be located to

allow maximum soak time for any chemicals applied to the wheels. The spinners can be

placed below an existing piece of equipment to save on space.

The driver and passenger side DuraBlasters® should be in line with each other

across the wash bay width.

The outside of the driver side base plate should be 43” from the inside guiderail

of the conveyor as shown on the previous sketch.

The outside of the passenger side base plate should be 140” from the outside of

the driver side base plate.

Use two 3/8” x 3-3/4” anchors to secure the DuraBlaster® to the floor at these

dimensions. There are 4 mounting holes in each base plate but only 2 diagonal

anchors are needed for each side. Mark the floor, drill one 3/8” hole and insert

one anchor.

The driver side and passenger side Rotating DuraBlasters® have the same

components but are assembled slightly differently. There are two different flow

controls located under the back cover. One flow control is shiny silver and may

be installed into the top or bottom of the cylinder. The other port of the cylinder

will have an elbow that connects an airline to a brass flow control protruding

through the cover.

The brass flow control has the highest resolution, and is used to adjust air out

of the cylinder during the wheel tracking rotation.

The silver flow control is used to control air out of the cylinder during return

rotation. The assembly with the silver flow control on the bottom should be

installed on the passenger side of the tunnel.

Note: Step 3 is continued on the next page.

12 Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL054